|

As a couple of you may already be aware, I design and build various things of an electro-mechanical nature. I've recently produced a few limited sets of exhaust tips for

|

|||||||

|

|

LinkBack | Thread Tools | Display Modes |

|

|

#1 (permalink) |

|

Base Member

Join Date: Aug 2011

Location: Austin

Posts: 142

Drives: 2JZJeep

Rep Power: 14     |

As a couple of you may already be aware, I design and build various things of an electro-mechanical nature. I've recently produced a few limited sets of exhaust tips for the HKS resonated systems, and one request I've gotten several times over (for other tips as well) is the burnt look. Being a scientist/engineer, I've decided to tackle the issue and share my progress with you here.

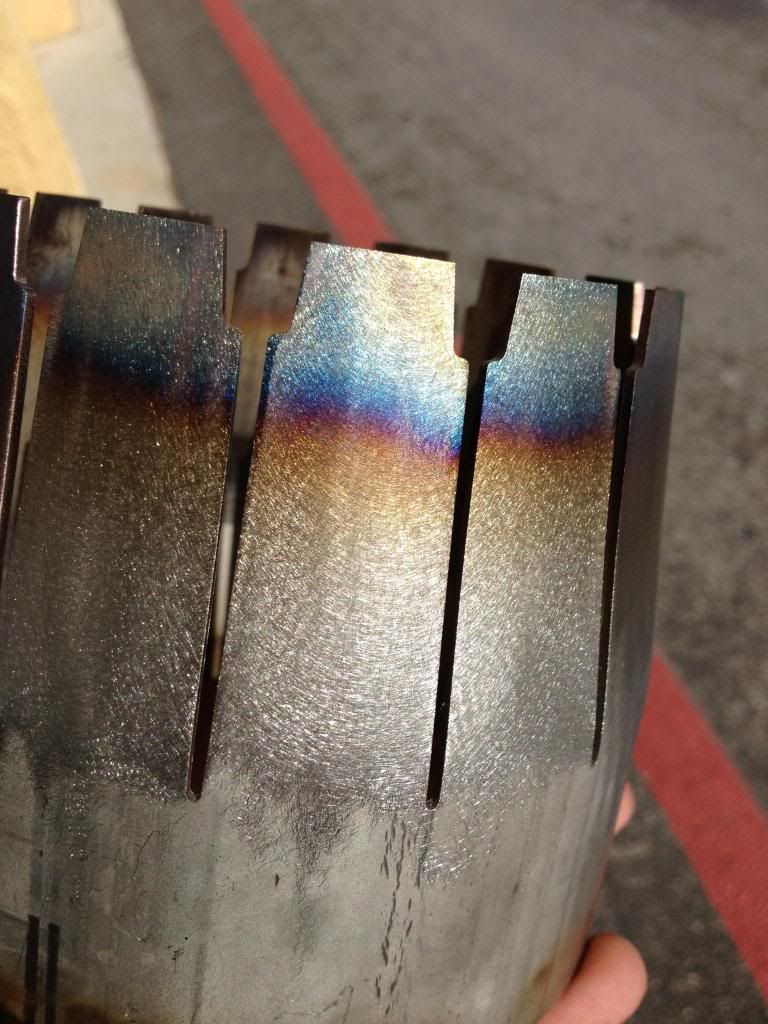

First a little background on the phenomenon, since without understanding what we are doing when we do it, we have no hope of acquiring any semblance of control over the results. All metals oxidize...except gold. In the cases of Ti or stainless alloys, the layer of oxidation that develops is invisible to the human eye. The reason we perceive color when the material is exposed to high levels of heat is because the heat causes a chemical reaction between the oxygen in the atmosphere and the resulting layer of oxidation has a thickness that interferes with certain wavelengths of light as they reflect off of the material. This is the same effect that makes certain insects appear to look like they have a metallic green, blue, purple, or pink hue to their shells or wings and why a super thin film of oil on water creates the rainbow affect in a puddle of water on the street. Depending on the thickness (measured in nanometers...just like wavelengths of light in the visible spectrum) different colors are either blocked or reflected. So heating stainless to a specific temp will force it to develop a certain thickness of its oxidation layer, which will result in a specific color being "produced". Using some spare parts from my previous GTR Afterburner tips, I have begun experimenting with the specific methods, techniques, times, and temperatures in order to develop a variable recipe that will allow me to make sets of burnt tips with beautiful, vibrant, and uniform colors. I'm going to use different heating methods along with different techniques for material preparation in order to generate a wide variety of results and narrow down which methods produce what I consider to be the "best" results. Varying the time will yield lighter or darker colors. Experiment 1: What affect does the material roughness have on the color? Initially I used one formed outer tip and prepared the fins 4 different ways. I left several raw, I used a grinder with a flap disk on 3 fins, I used a brass wire wheel on 3 fins, and I used an orbital sander on 3 fins. I then took a handheld Propane/Mapp gas (yellow bottle) torch and proceeded to hand-heat steel. RAW  FLAP DISK  WIRE WHEEL  ORBITAL SANDER  I discovered immediately that without implementing some sort of mechanical control of the tip, getting any semblance of even heating on each fin is quite difficult...especially when you have standards as high as mine. I have a solution for this already, I believe. Another experiment was to heat the edges of the tip using an electric stove burner. While this worked and did yield more even results, it was painstaking and time consuming. The burner being a coil worked against being able to heat the fins perfectly evenly.  I have ordered some polishing supplies for stainless steel from Eastwood and will be experimenting to see how bright I can get the stainless oxidation layers. I am sure it will never be as bright as the effect is when done on titanium, but I should be able to get some decent results. Over the next week or two I will be furthering this and I will share most of everything I learn. I might have to keep a secret or two for myself, however. You understand.  -Chad K

__________________

http://i54.photobucket.com/albums/g9...uitySigpic.jpg We exist to do great things. FringeXVO-Mech Design Fab Last edited by FringeXVO; 06-22-2013 at 06:14 PM. |

|

|

|

| Bookmarks |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| *NEW* Fringe XVO "Afterburner" Exhaust Tips | FringeXVO | Exhaust/Intake | 267 | 08-08-2018 11:24 PM |

| [FOR SALE] Motordyne 5" Burnt Titanium Exhaust Tips | tibal | Parts for sale (Private Classifieds) | 4 | 08-23-2012 08:16 AM |

| [FOR SALE] Motordyne 5 inch burnt tips " new " | NeverBoneStck | Parts for sale (Private Classifieds) | 8 | 07-05-2012 04:22 PM |

| For Sale: Fast Intentions Exhaust; Stainless with 12" Resonators | mh0187 | Parts for sale (Private Classifieds) | 16 | 06-30-2011 08:54 PM |

| Z1 Motorsports 370Z Stainless Steel 2.5" Test Pipes | WxMan | Parts for sale (Private Classifieds) | 16 | 12-12-2010 09:37 PM |