|

Not my car, but hot damn these look great. I will definitely be getting these as a nice alternative to the te37's. SSR Type C-RS They come in...... ( correction

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

#1 (permalink) |

|

Base Member

Join Date: Jul 2009

Location: $an Francisco

Posts: 7

Drives: soon to be 370z

Rep Power: 16  |

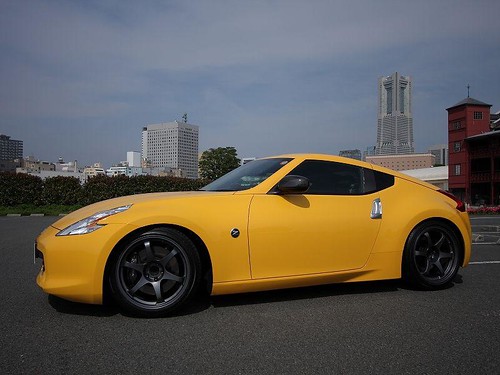

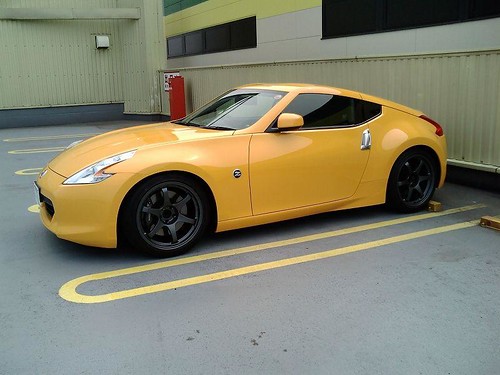

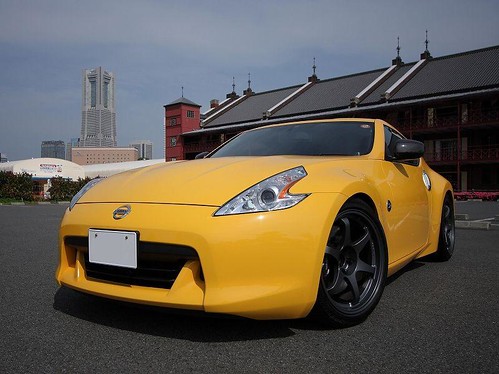

Not my car, but hot damn these look great. I will definitely be getting these as a nice alternative to the te37's.

SSR Type C-RS They come in...... (correction, only Bronze and Gun-Metal.) I kinda like the decals too.

Last edited by Organik; 07-27-2009 at 07:24 PM. |

|

|

|

|

|

#2 (permalink) |

|

Lifetime Premium

Join Date: Nov 2008

Location: Montreal

Posts: 22,357

Drives: E46 M3

Rep Power: 1765            |

these stickers would look cool on the rims

SSR side spoke wheel Decal Sticker on eBay.ca (item 270420043059 end time 02-Aug-09 06:29:42 EDT) or SSR Wheel Spoke Vinyl Decal Sticker SP 1 Rim Alloy on eBay.ca (item 390070711625 end time 17-Aug-09 02:13:38 EDT) Last edited by nogoodname; 07-27-2009 at 11:51 AM. |

|

|

|

|

|

#5 (permalink) |

|

A True Z Fanatic

Join Date: Nov 2008

Location: Seattle

Posts: 1,722

Drives: z34 - R1

Rep Power: 490            |

These come in 370z offsets.

How much do you think these wheels are? If they're priced near te37 then I would rather get volks because they look better but also volks have rear lip.

__________________

2010 k23 H&R sport springs / Spc rear camber arms / SSR SP1 / Berk cbe / Varis cf lip / Nismo S-Tune side skirts

|

|

|

|

|

|

#7 (permalink) |

|

A True Z Fanatic

Join Date: Nov 2008

Location: Seattle

Posts: 1,722

Drives: z34 - R1

Rep Power: 490            |

I believe this is the fujimoru 370z so that is a rear carbon overlay.

__________________

2010 k23 H&R sport springs / Spc rear camber arms / SSR SP1 / Berk cbe / Varis cf lip / Nismo S-Tune side skirts

|

|

|

|

|

|

#8 (permalink) |

|

Base Member

Join Date: Jul 2009

Location: $an Francisco

Posts: 7

Drives: soon to be 370z

Rep Power: 16  |

About $700-$730 each in 19 inch. Slightly cheaper than the TE37's depending on where you get them.

.... plus, these have the nicely tapered spokes. So sex! I wonder if you could get these made with the fat lip? |

|

|

|

|

|

#10 (permalink) |

|

Base Member

Join Date: Apr 2009

Location: Miracle Mile, CA

Posts: 27

Drives: My Wife Crazy

Rep Power: 17  |

Looks good! I can't remember: is SSR forged? I seem to think they use semi-solid forging and I never understood if that was different from any other kind of forging.

|

|

|

|

|

|

#11 (permalink) | |

|

A True Z Fanatic

Join Date: Jan 2009

Location: Los Angeles

Posts: 1,666

Drives: 370Z with NAVVVVV

Rep Power: 285            |

Quote:

Indeed. |

|

|

|

|

|

|

#12 (permalink) |

|

Base Member

Join Date: Jul 2009

Location: socal

Posts: 25

Drives: 370z

Rep Power: 16  |

As far as i know they only offer bronze and gun metal for the type-c. The flat black was only offered by Tire Rack awhile ago but its discontinued now.

http://www.ssr-wheels.com/wheels/typec_171819.asp As for the SSR comp that was discontinued long ago. Last edited by DuReichstSoGu; 07-27-2009 at 04:01 PM. |

|

|

|

|

|

#13 (permalink) | |

|

Base Member

Join Date: Jul 2009

Location: socal

Posts: 25

Drives: 370z

Rep Power: 16  |

Quote:

SSR knew, though, that higher quality, lower cost, well-designed wheels were what the customer wanted and in 1991 learned of the advanced technology of semi-solid forging (SSF). This technology was being used to produce parts for the aircraft industry where low weight and reliability are crucial. So, SSR obtained a license to use SSF technology from Alumax Laboratories and after one year of research and development built their now-patented wheel manufacturing plant in Nara, Japan. The Advantages of SSF Semi-Solid Forging (SSF) Manufacturing Technology Extracting the best qualities of casting (unlimited design possibilities) and forging (lightweight and high strength) and combining them in the uniquely new mass production manufacturing process of SSF. Forging is the process of forcing a solid billet of aluminum alloy between forging dies under an extreme amount of pressure. This creates a finished product that is very dense, very strong. Less aluminum alloy is used to meet the strength requirements for the intended application resulting in very lightweight wheels. The costs of tooling, development, equipment, etc., limit the designs available and usually demand a high price in the aftermarket. Many racers have been willing to pay the premium price required to acquire strong wheels that are lightweight. The casting process, pouring molten metal into a mold, offers a very reasonable production cost and is a good method for casting designs that are more visually oriented or when reducing weight is not a primary concern. The high heat used introduces impurities into the metals and results in a more brittle, branch-like microstructure that is more susceptible to breakage along its weak points. Cast wheels can be equal in strength to forged wheels but, in order to meet the demands for use on a vehicle, more alloy is used resulting in a heavier wheel. Cast wheels offer consumers the greatest variety of designs at the lowest price and are adequate for most street use applications. Further research led scientists to develop a process whereby mechanically agitating (stirring/mixing) alloys during the solidification process changed the original microstructure of the alloy from a branch-like structure to a globule granular structure. Alumax then perfected the aluminum stirring process, Magneto-Hydro Dynamics (MHD), and created the basis of SSF technology which results in a pure cylindrical alloy billet consistently free of non-metals, gasses, oxides and other impurities. This MHD billet, when heated to a specific temperature, attains a semi-solid form (consistency of soft butter). After pressed into a mold at a very high rate, the shaped product retains the preferred globule granular microstructure. The end product is very dense and strong allowing the manufacturer to use less aluminum alloy and still meet the engineering criteria for the intended use. Casting's Conventional Branch-Like Alloy Structure SSF's Semi-Solid Globule Granular Alloy Structure Today, SSR is the only wheel manufacturer in the world to produce SSF aluminum wheels. SSR continues to research ways to further develop SSF, creating beautiful, lightweight and strong wheels that benefit the customer via function and beauty as well as enhanced performance—all at a lower cost than forging or casting |

|

|

|

|

|

|

#15 (permalink) |

|

Banned

Join Date: Feb 2009

Location: CA

Posts: 118

Drives: MB Base 6MT w/Sport

Rep Power: 0  |

SICKKKKKK!!! Loving the bumble bee approach, and SSR's are always an awesome wheel to run. We sell a bunch of SSR's and definitely recommend them for strength, style, weight.

-Steven @ Amplified |

|

|

|

|

| Bookmarks |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| What about this type of wiring/setup for base? | LattimerII | Audio & Video | 5 | 07-08-2009 04:30 PM |

| What type of speakers are in the 370z? | LattimerII | Audio & Video | 0 | 06-29-2009 11:44 PM |

| Filter type? | NotmyGTR | Nissan 370Z General Discussions | 11 | 06-15-2009 12:27 AM |

| Type of wax for VentureShield? | ocfoilist | Exterior & Interior | 7 | 04-27-2009 09:53 PM |

| HKS VAC TYPE Z34 370Z Tuning Chip 01.22.09 | AK370Z | Nissan 370Z General Discussions | 5 | 01-24-2009 11:13 PM |