|

|

|

#229 (permalink) |

|

Enthusiast Member

Join Date: Feb 2014

Location: Houston

Posts: 254

Drives: Race, Repair, Repeat

Rep Power: 4639            |

You never know who you'll run into at Jtran Motorsports!

__________________

2007 G37S [VQ37HR] Sedan 6MT - Fast Intentions Stage 3 TT - @ttv36 #tptoons |

|

|

|

|

|

#234 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

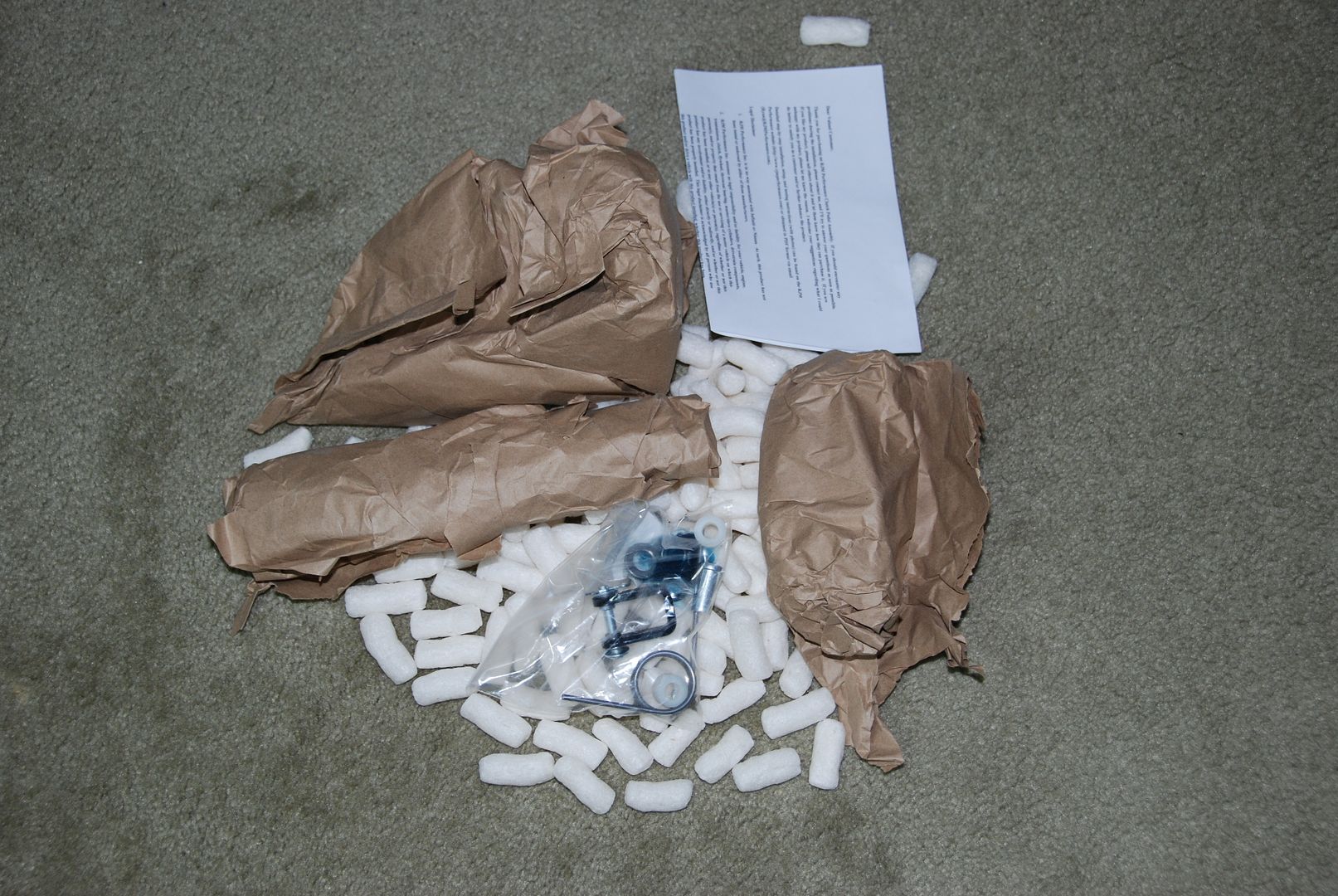

Some new toys came in, RJM clutch pedal and Random Orbital multi speed polisher.

comes in nice box very well packaged. Ryan kept me updated via e-mails on pedal progress. A+ on that end. He emailed me on received $ transfer, again when he started assembly of the pedal, again when it shipped! It came very well packaged. Each part of the pedal was separately wrapped. The Parts of the pedal were per-greased and in a large zip lock bag to keep other parts from getting greased up. I have to wait for a nice non raining day to get this thing installed. I really hope it makes the driving experiences a lot better and allow a better launch.       YzGyz |

|

|

|

|

|

#235 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

What a struggle to put that pedal in! It's not a hard install, just a tight spot to work. Anyhoo, I made a install vid. I gave the car a test run around the block. It's a lot easier to drive now. Pedal works nicely. I'm also better able to slip the clutch. I need to try this pedal at the track to see if it helps with my 60'. however, I'm going to wait until I find me some drag radials first. I have it set at 80% (full 10 turns lefts to lock, then 2 turns right - 80%).

https://www.youtube.com/watch?v=WXX0pwSbwv0 https://www.youtube.com/watch?v=5je0...ature=youtu.be YzGyz |

|

|

|

|

|

#236 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

I have drove some miles with the RJM clutch pedal and wow!! It's nice! The Specialty Z 6 puck was hard to drive with. On a scale of 1-10, it was a 10. Every person that has tried to drive my car has stalled at least once. This includes people that have had 1000'so far mile driving a manual and cars with decent power. It was just about impossible to ride the clutch prior to the RJM. Now, I can ride the clutch and have way smoother shifts. Shifting is now a 4/10 so imo it's awesome. I just need to try it out at the track and see if it helps with my launch. However it will be an unfair comparison because my new SPL camber arms and SPC toe bolts cane it. I also plan to get a set of NT05R shoot for mid 11's. I won't be installing anything for a while though.

YzGyz |

|

|

|

|

|

#237 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

It's been a little busy cleaning and the new years coming and all (Lunar New Year, TET). I have a new cool toy coming in a few days. I have been cleaning the garage out making space. It is not an easy task. I finally got back to the gauge pod build. It's almost done.

things I would change if I were to do it all over. 1-foget the paper mache. I though and found an easier way, plaster! I kept and used my old fiberglass thing I made because it was still good and fit alright but I could of had a lot easier of a time making it. Plaster could be bought at the local hardware store for like $9 a big bag. So you just have to tape or plug up holes and deep crevasses, mix up the plaster and pour it in. Let it dry and pull the mold out. You can then flip that mold over, make a hard boarder for it out of cardboard, put something as a release agent over the original plaster and then pour new plaster over the old to make a copy of the dash. 2-buy good sandpaper and tools to hold/use it. I bough cheap crap paper and after a few strokes, it no longer sands. 3-buy a set of cheap files. They make rough sanding things a lot faster and easier. Anyhow, here are some pics of the progress. It's basically done. I use the plaster to make a mold to know where to put things.  th thin part in the middle cracked and broke but that's ok. It served its purpose. I used 1 side of the plaster piece to hold the pipe int he correct position as I made a pvc piece to hold the pipe in place on the other side.  I skipped through a lot of the build process because I was thinking how to accomplish certain things and looks of the pod and forgot to take pics. I built a total of 4 different pod brackets to hold the gauges. That took a whole lot of time and that is also a reason why I didn't have build pics in between. I was just frustrated on how the thing looked and would start all over again. Anyhoo, she is almost done. I had sanded her down super smooth thinking I was going to spray a layer of primer, black, and clear coat over her and be done. I decided to add texture to her so I googles around and found that they ahve rattle cans of texture stuff. The hardware store has a selection of looks in different colors. That have a Hammered metal look, glow in the dark spray, matted, stone type, and many more. I picked the stone type. Here a picture of the pod waiting for a clear coat. She was sprayed with first the primer (I got the black primer), then the Stone spray (spray this stuff at a good 12'' distance. This stuff sprays too much otherwise. It is such a friggin cool product!), then black primer again. Next up is the clear. If it's too shiny, I will pick up a matted clear and spray it over the gloss one.  I'll post up the thing once finished and installed in the car later today. Edit: Here it is in the car. It looks lice from the front. The top down view is ehh from the wires. There is no way to hide the wires w/o ruining my instrument cover thing. I don't want to do that plus I'm sitting hte the driver's seat so who cares, lol.  driver seat view.   I now have 1 big problem and 1 minor problem left. BIG: I need to figure out how to use the EBC. I had it installed, Johnny tuned it with the EBC running and all the good stuff. I just don't know how to use it. I don't want accidentally over boost it and BOOM! Minor: The pods are attached to the dash with heavy duty locking velcro. The darn velcro glue backing wont stick the the dash too well. It will stay in place fine. It will even withstand a light tug. I want it to stick STRONGLY enough to hold a a decent tug without ruining my dash. Anyone know of a adhesive or glue that can stick to the dash really well but wont mess it up? YzGyz Last edited by YzGyz; 02-04-2016 at 04:14 PM. |

|

|

|

|

|

#238 (permalink) |

|

A True Z Fanatic

Join Date: Dec 2010

Location: Houston

Posts: 14,532

Drives: '10 G37 6MT

Rep Power: 2465057            |

Major problem answer - throw Johnny a six pack of beer to explain how to use the EBC. Mines easy turn on for full boost turn off for low boost and change map.

Minor problem - I got nothing but can offer a few things if you finally decide you want it to be permanent. |

|

|

|

|

|

#239 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

And the new toy is home! So frigging cool! I got this used low rise scissor lift for a really good deal. It weighs a few hundred pounds but a 2x4 to leverage and lift her onto 3 furniture dollies and she moves around the garage beautifully. The hydraulic power unit is labled Rotary. Rotary and Mohawks are really good brands. The lift itself don't don't look like a Rotary but a Bendpak. I have not really taken a good look at it all around other than to check that it lifts and work correctly and wear and tear. These things can be had for around $550 used if you find one. I got it cheaper than that but I got lucky. She plugs into the 110 wall socket and she is ready to lift. Never again will have have to "stock pile project" to do them all at once. I hated lifting the car and setting jack stands. Now, I just drive over the 2x10 ramps, turn engine off, e-break, set lift block, and press the button and up she goes! So very cool!

We use the Shelby to position the lift int he garage as that is the longest and biggest car we have.    This thing is plenty high to do things under the car. There is plenty of room and clearance to do work under the car. This is a MX5 on the lift. Here are some underside pics to show clearance and accessibility of the underside. These pictures are taken from the front of the car going back.   In this picture you can see the cross member of the lifting platform and what you have to work with.    YzGyz |

|

|

|

|

|

#240 (permalink) |

|

A True Z Fanatic

Join Date: Jun 2013

Location: Houston

Posts: 1,449

Drives: 2010 Nismo

Rep Power: 63            |

|

|

|

|

|

| Bookmarks |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Turn knob and A/C turns on. Can i turn it off? | zmyride | Nissan 370Z Owners Manual / Service Manuals | 18 | 04-24-2015 01:17 PM |

| Turn down for what | RoadsterST | Movies / Celebrity Gossip / Entertainment / Music | 2 | 03-28-2014 03:43 PM |

| My turn | RITDR | Audio & Video | 4 | 05-19-2013 06:49 PM |

| My turn!!! | alvinmathew88 | Nissan 370Z Pricing / Ordering Discussions | 14 | 02-03-2011 06:44 PM |

| First Turn-by-Turn Navigation App for iPhone: XROADS G-Map Review | AK370Z | The Lounge (Off Topic) | 5 | 12-12-2009 12:33 AM |