Some info from the intraweb...

"TORQUE CUT CONTROL (AT HIGH ENGINE OIL TEMPERATURE)

The ECM receives engine oil temperature signals from engine oil temperature sensor.

To avoid VVEL performance degradation, the ECM performs the engine torque cut control at high engine oil temperatures.

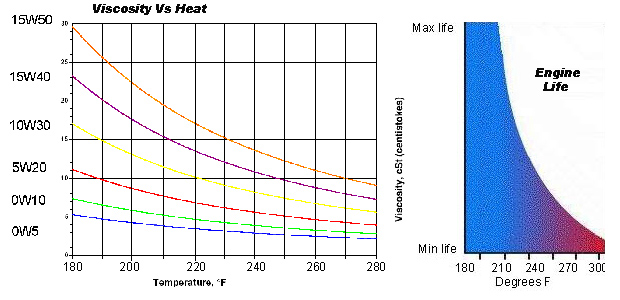

If engine oil temperature is too high, engine oil viscosity will change. As a result, engine oil pressure is

decreased. This control affects the VVEL operating angle by operating the VVEL actuator sub assembly.

If this control is operated, engine performance will decrease, then maximum engine speed is reduced a bit (Various levels of Limp Mode depending on temp).

.

The VVEL is a fairly complex system, with a relatively high amount of reciprocating mass and multiple linkages. The lubrication demands are very high to ensure Nissan's life expectancy goals are met. The shearing loads and high pressures exerted on the oil dictate a proper viscosity be maintained in order to resist lubrication failure due to these loads. Because an oil's ability to resist shearing weakens as it gets hot and thins out; a phenomenon plotted as a function of viscosity and shear stability known as the Stribeck curve, it is essential that the oil maintain it's specified viscosity at the appropriate operating temperature. This is why Nissan has engineered a fail-safe which limits power until the oil cools back to its specified operating temperature, because at that temperature it should be at the proper viscosity to withstand the high loads of the VVEL system.