OK...A lot of you have been waiting for this. Given the controversy over oil temps you can either wring your hands, point fingers, assign blame and hope Nissan will do something, or just knuckle down,

spend a few bucks and take care of the problem yourself. Your car will like you for it. Actually my car does not seem to run exceptionally hot. Some frisky running in the hills of western NC last weekend rarely saw temps above 245. Regardless, I'm a fan of cool, be it intakes, engine compartment temps or whatever. A cooler was in the plan. I've done several before on Audi TT's so this was not new. I will have to say, the 370 layout made it much easier than I'm used to. I decided to go with a 180 degree thermostatic plate (Mocal) and a Cooler core that I've used before (Tru-cool). The choice of Aeroquipt socketless hose may be controversial, but I suggest you do a google search before rendering judgement on those. Lets get started:

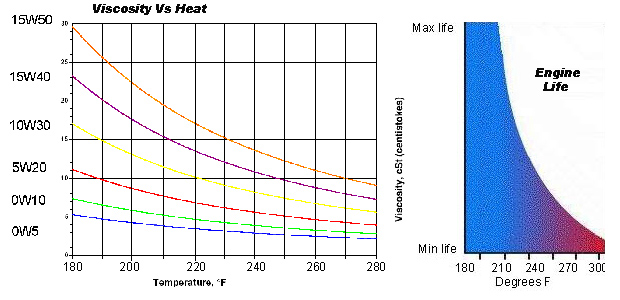

Why? A little research indicates:

"TORQUE CUT CONTROL (AT HIGH ENGINE OIL TEMPERATURE)

The ECM receives engine oil temperature signals from engine oil temperature sensor.

To avoid VVEL performance degradation, the ECM performs the engine torque cut control at high engine oil temperatures.

If engine oil temperature is too high, engine oil viscosity will change. As a result, engine oil pressure is

decreased. This control affects the VVEL operating angle by operating the VVEL actuator sub assembly.

If this control is operated, engine performance will decrease, then maximum engine speed is reduced a bit (Various levels of Limp Mode depending on temp).

.

The VVEL is a fairly complex system, with a relatively high amount of reciprocating mass and multiple linkages. The lubrication demands are very high to ensure Nissan's life expectancy goals are met. The shearing loads and high pressures exerted on the oil dictate a proper viscosity be maintained in order to resist lubrication failure due to these loads. Because an oil's ability to resist shearing weakens as it gets hot and thins out; a phenomenon plotted as a function of viscosity and shear stability known as the Stribeck curve, it is essential that the oil maintain it's specified viscosity at the appropriate operating temperature. This is why Nissan has engineered a fail-safe which limits power until the oil cools back to its specified operating temperature, because at that temperature it should be at the proper viscosity to withstand the high loads of the VVEL system.

(Note: The engine life graph is just a representation pulled from an article discussing 300,000 mile Porsche 911's and the effect of oil temps on longevity. Take it for what it's worth)

Have all your parts handy and do the pre-assembly (Parts list at my link below):

Total cost on this system, including a Thermostatic plate is $270 shipped.

10 AER-FBN1000 -10 Aeroquip Socketless Hose, Black $43.70

2 AER-FCM2039 Aeroquip 90 Degree Male Elbow, Aluminum - Aeroquip 90 Degree Male Elbow, Alum. -10 to 1/2" Adapter $22.48

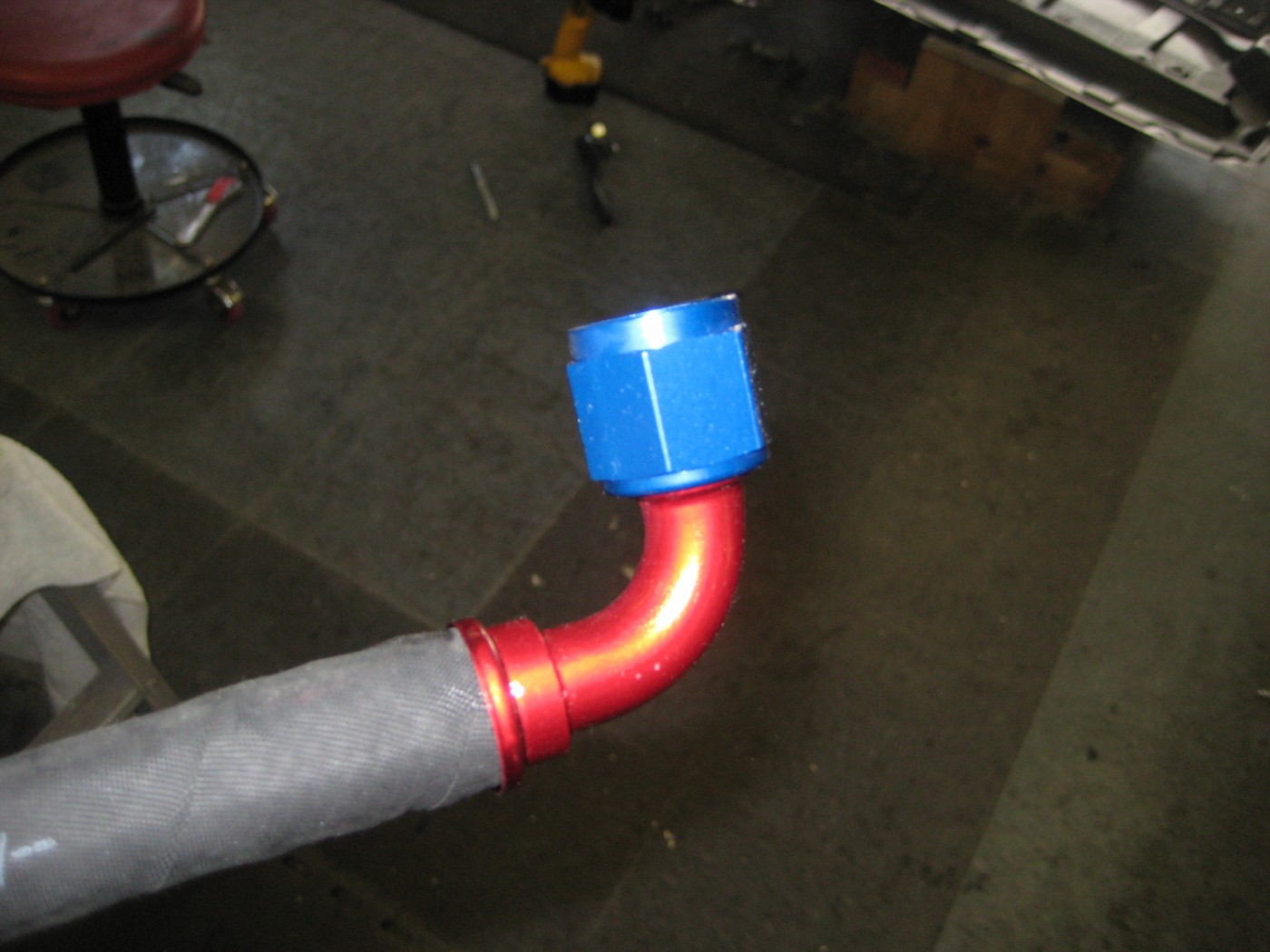

2 AER-FCM1534 Aeroquip Socketless 90 Degree Elbow Fitting - -10 Aeroquip Socketless 90 Degree Elbow Fitting $33.36

2 AER-FCM1514 Aeroquip Straight Socketless Fitting - -10 Aeroquip Socketless Straight Fitting $14.50

1 MOC-2BM810A Mocal 1/2" x -10 ORB fitting $15.99

1 MOC-SP1FT Mocal Sandwich Plate- 20mm Thread $86.95

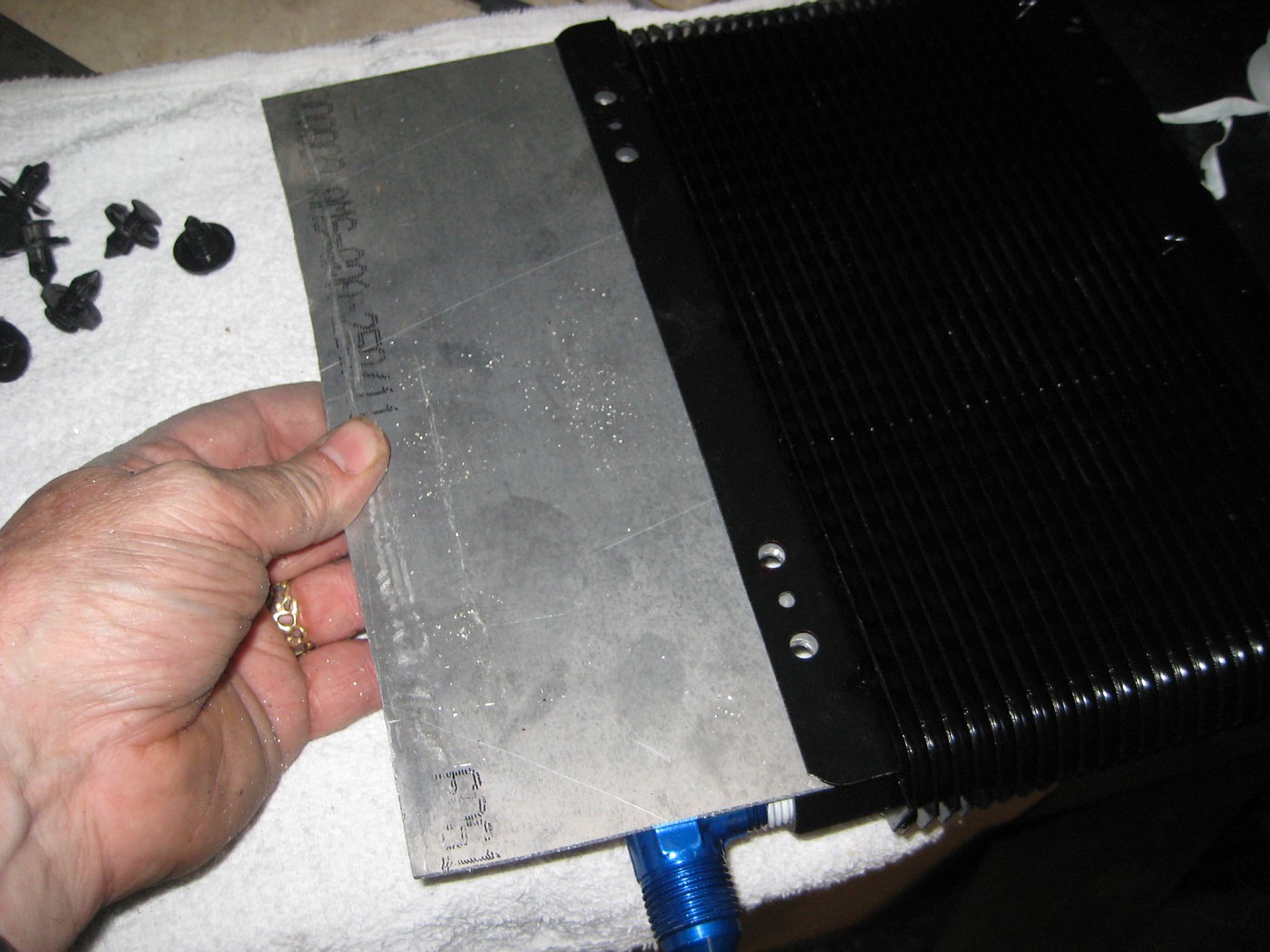

1 TRU-L7B TRU-Cool 24 Row Racing Oil Cooler $44.95 (11" x 5.75" x 1.5")

Shipping Rate: $8.85

Subtotal: $270.78

Alternative Stainless and socketed hose assembly, use these parts in lieu of the socketless hose and fittings above. It is recommended you go with this set-up if you plan to do any tracking of your car where temps may be elevated, and engine movement on the mounts may be exaggerated... : Cost difference is approx + $30

10' section of Aeroquipt Stainless AN10 hose AER-FBA1000-10 $75

(2) Mocal 90 degree fittings MOC-F90-10 @ 15.15 each $30.30

(2) Mocal straight AN10 connectors MOC-FS-10 @ $7.49 $14.98

More detail on page 13, post 189 on the stainless lines

From Racer Parts Wholesale

http://www.racerpartswholesale.com

Notes on installing NPT fittings into the cooler:

http://www.mechanicsupport.com/articleFittingTight.html

A high temp sealant is probably the best sealer here, such as Loctite #567

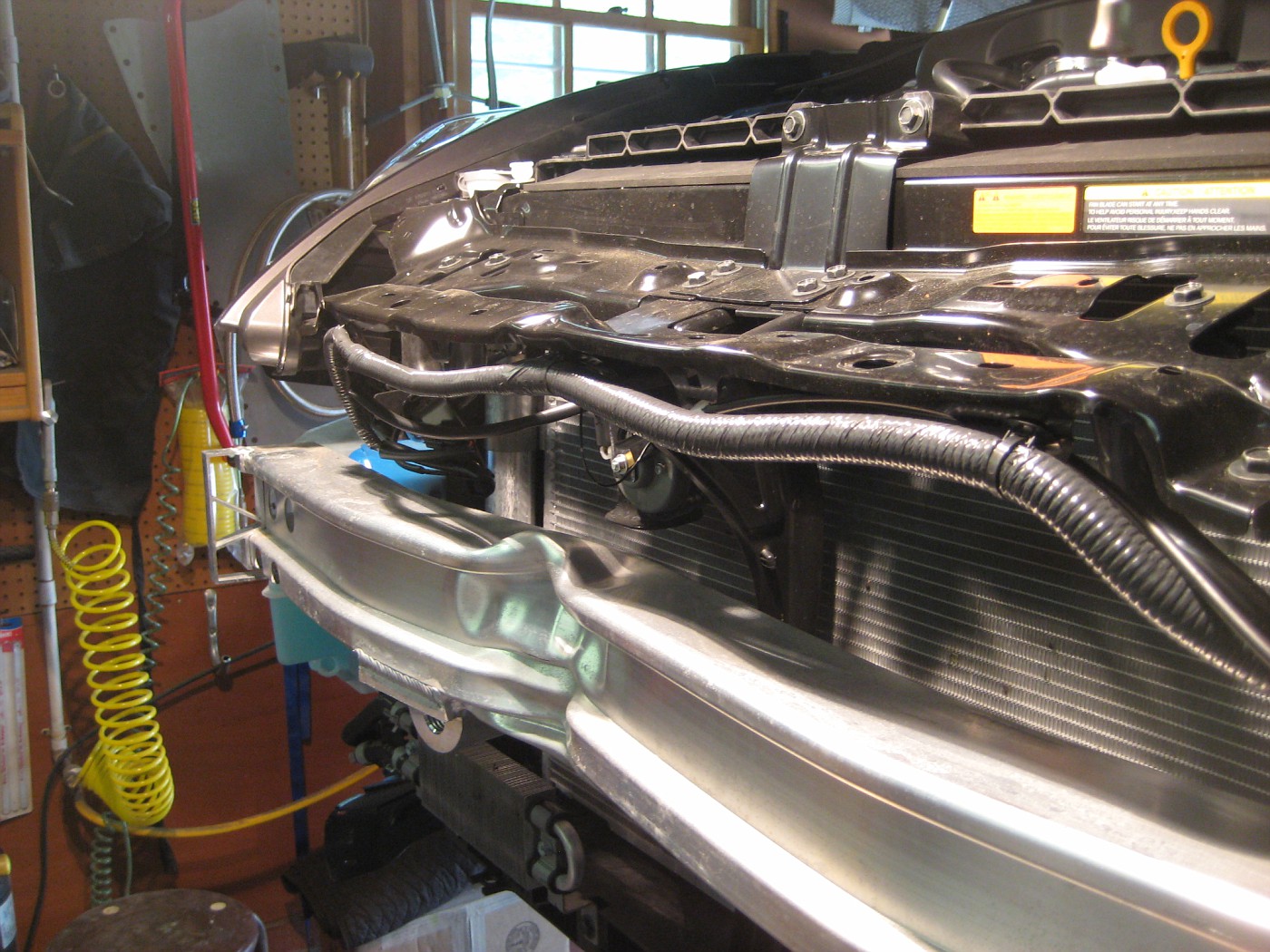

Get the car in the air and pull off the nose and lower cover. This is an easy process documented elsewhere ( I have a lift which does make it easier!)

Oh yeah....Ignore my accident damage (soon to be fixed) let's just say the impact bar did its job when I got shoved into that Jeep!

Next up, mount the 20mm thread Mocal sandwich plate. Just screw the adapter onto the existing Oil filter threaded nipple:

and decide where you want to route the lines. AN10 lines are pretty big and will need good radius clearances

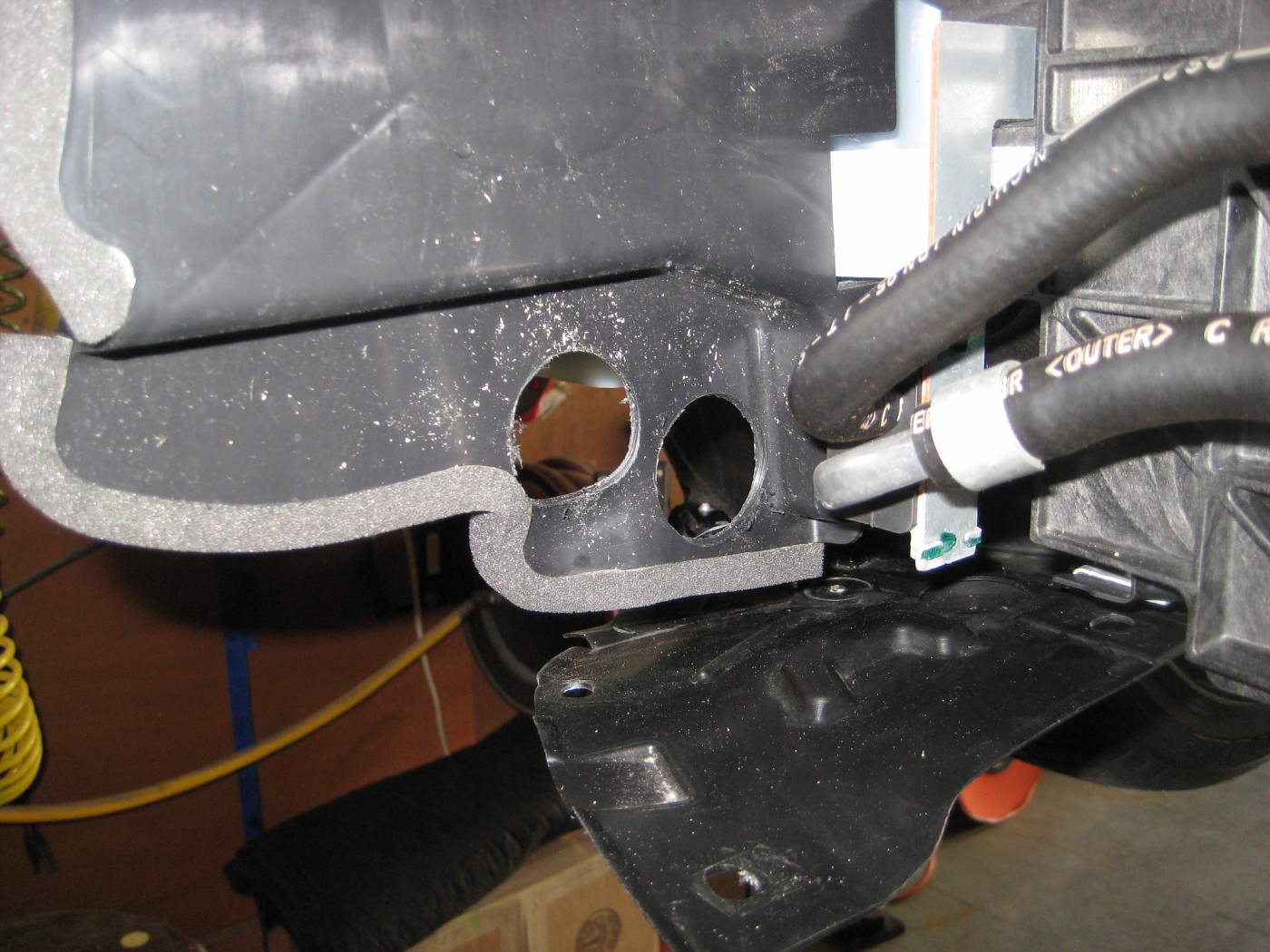

Cut the Hose holes in the rear:

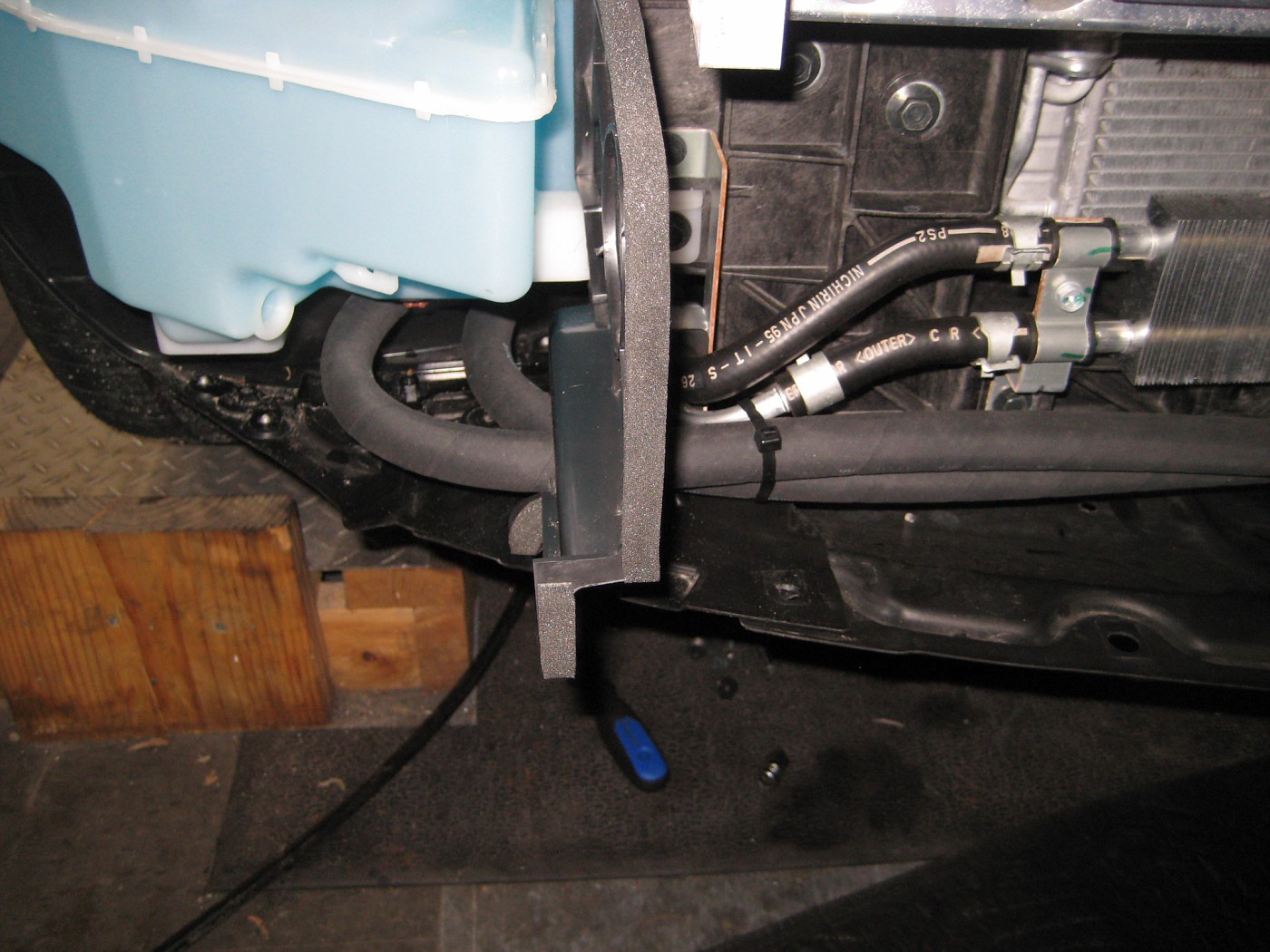

and the front. These panels are held in place with the plastic push pins or slide in tabs and remove easily.

Mock up a bracket for the cooler:

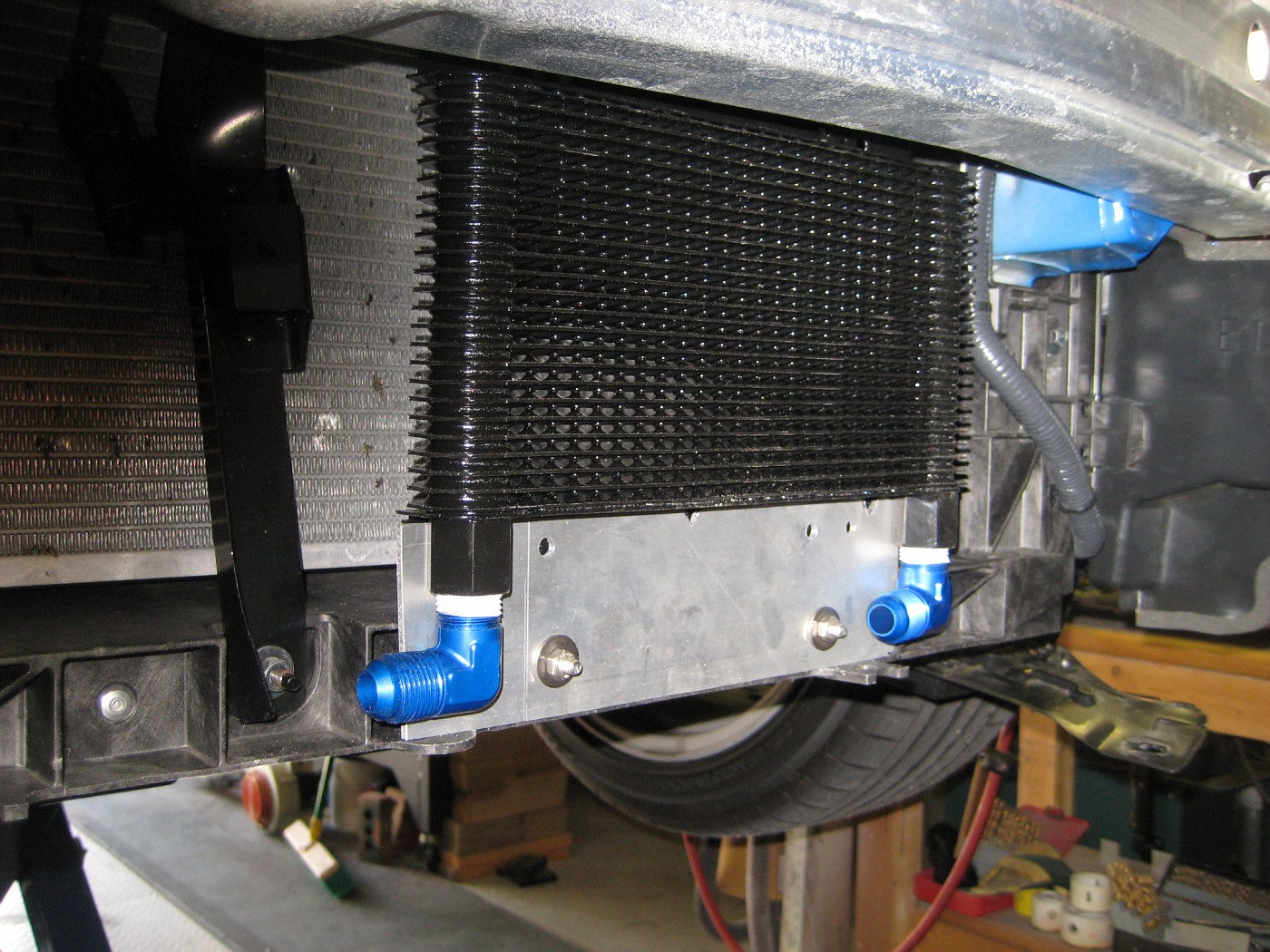

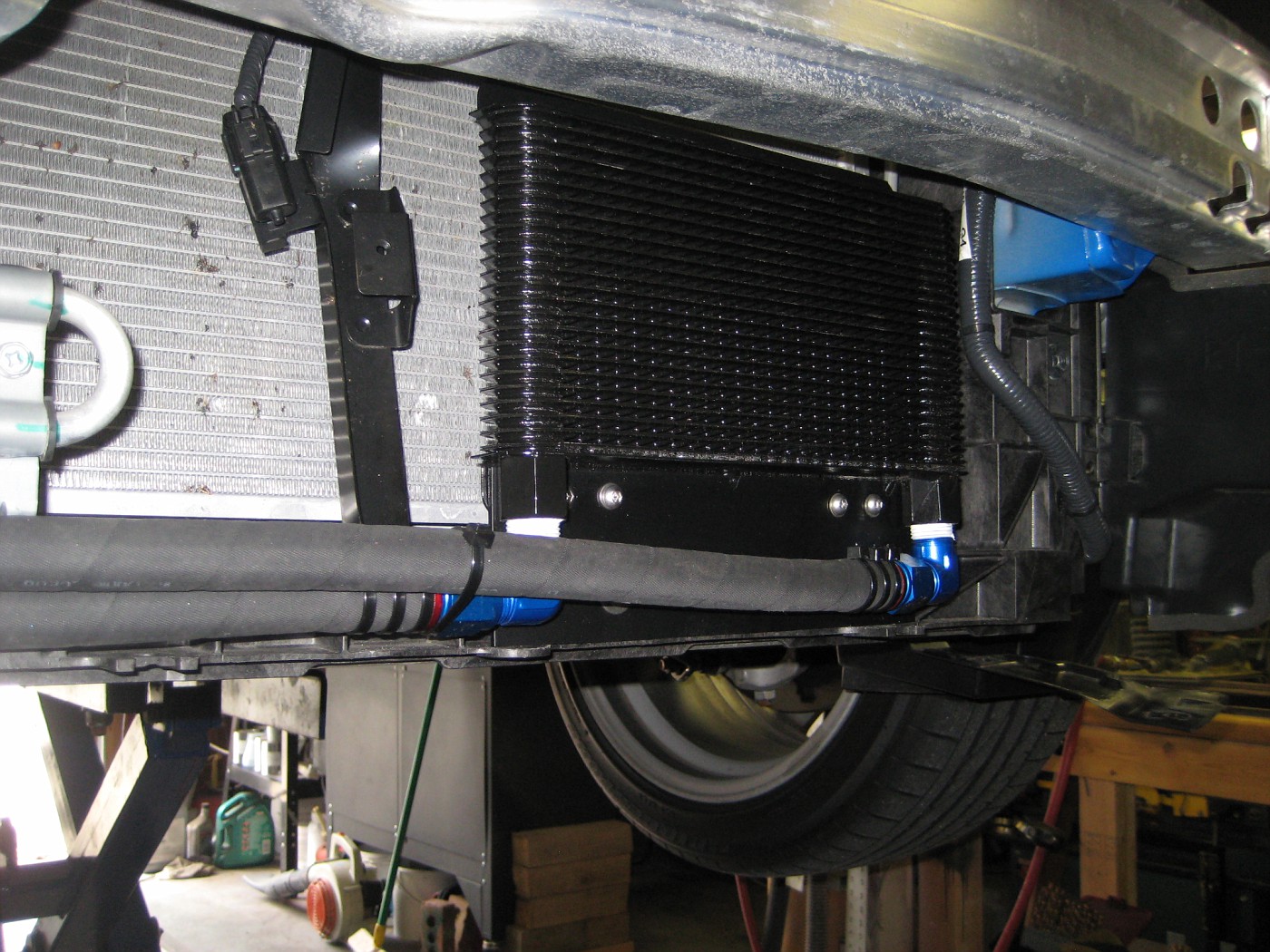

Powdercoat it (what I did) or paint to make it stealthy. Mount it with stainless M6 bolts and Nylock hardware using existing holes on the lower composit radiator support.:

Measure and lay-out hoses. You'll need to buy 10 feet:

Install ends...The socketless Aeroquipt lines make this a piece of cake. They just push on and are good to 250 psi, kinda like a Chinese finger handcuff :-) You'll need a 49" and a 63" hose (actual hose length, not including fittings):

Click here and scroll to the bottom for hose assembly instructions:

http://64.202.180.37/files/phosend.pdf

For information and pictures on the socketed style Stainless hose and fittings, see page 13, post 189

While your at it, upgrade your filter. See this thread

http://myg37.com/forums/engine-drive...otsa-pics.html

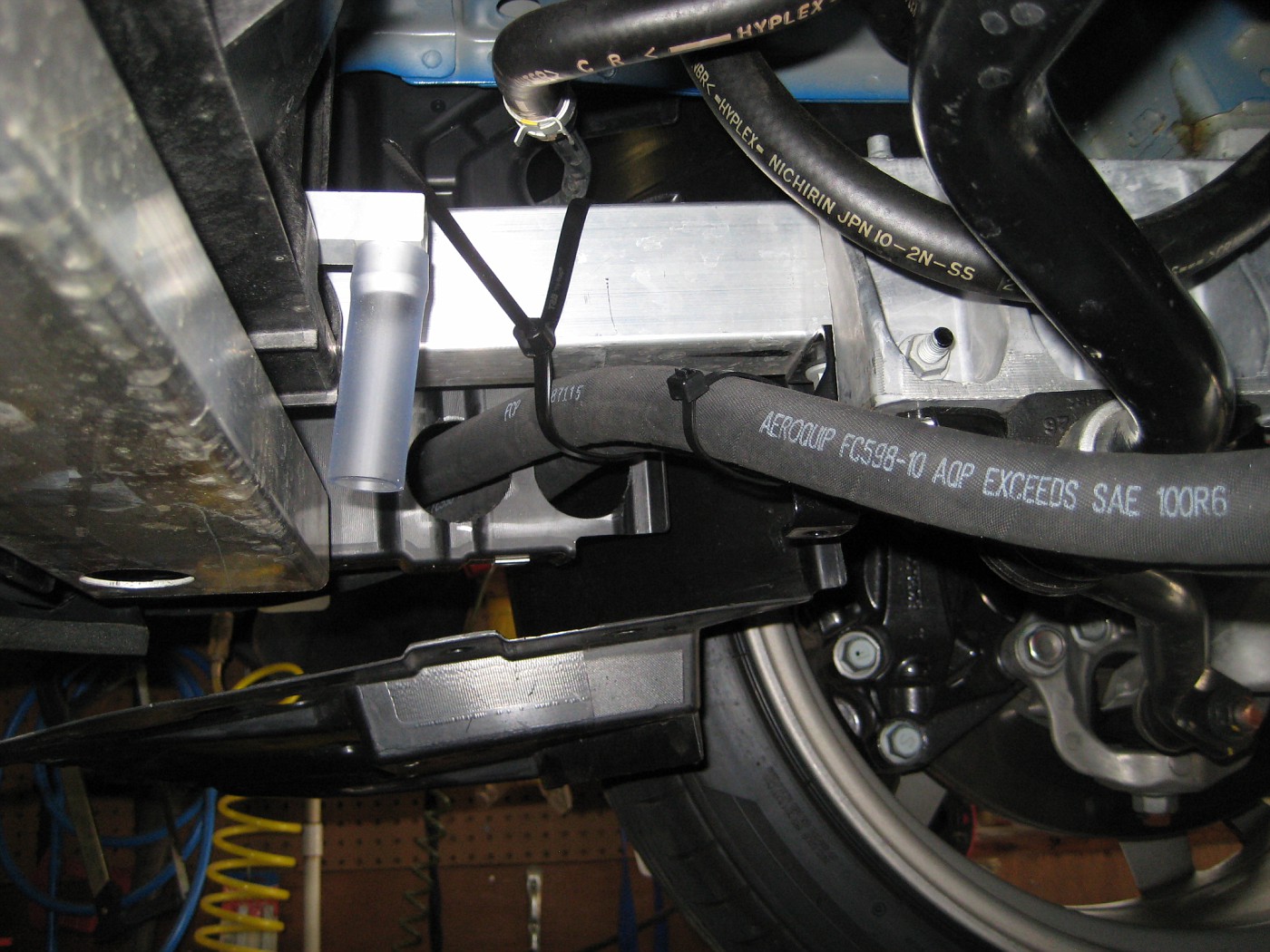

Hook up fittings and route lines:

Check everything carefully and fix hoses in place to avoid chafing and t maintain your radius bends:

Nice clean install, Have a beer, admire your work. All done:

Cooler with new Fang Vents mounted:

Upon start up there were Zero leaks. Took the temps up to about 185 on the lift with no issues at all.. I have not road tested yet as I need to get the nose back on. I'm looking for about a 20 degree reduction in temps and will report back once road tested.

Road Test Update:

went out in the country today and thrashed the car about for 45 minutes or so. Ambient temps 75 degrees, average coolant temps 184, Average oil temps 190. I had to work hard to get it to 200 degrees and it would not get hotter than that. I'm seeing a 20-25 degree average reduction from what I would expect to see without the cooler under similar drive conditions...

5/19: Another drive today to run some errands. 56 degrees ambient, Oil stayed between 190-195. Very close to paralleling the water temps..

5/20: Ambient temps 80 degress. Pushed it a bit but only saw temps in the 195-210 range.

6/25: Ambient temps are a little hotter these days (85-90) and the oil temps seem to be holding in the same range. 400 miles since install. Day to day around town 195-200. Hotrodding around out on the country roads 200-215

9/8: Several months and 2000 miles since the install (3500 miles total)l. Daily temps continue to average 190-195. Pushing the car, maybe 210. I have yet to see temps over 225 on Pennsoil dino oil. Full synthetic to be added at the next change at 4K.

Some notes: This is not a difficult install, even when rolling your own with a Bag 'O parts. If you are at all squeamish about building a bracket, or putting hoses together, then by all means buy a pre-fabbed kit from Stillen, GTM or DDM. You can save a few bucks going the route I went, upgrade some components and have the satisfaction of a solid DIY. A thermostatic plate should be considered a necessity for anyone living in the Northern climes or anyone considering a larger cooler. None of the pre-packaged cooler kits for more money (except the GTM) seem to include this. Buyer beware. The only difference with this install is you have to fab up a bracket and assemble your own hoses. Both these tasks are very easy. Total cost was $270 including shipping for the component parts. Time involved was about 4 hours taking my time and a few beer breaks. You'll now need just over 6 quarts for a complete fill which, in itself, will aid in cooling due to the new +1 quart capacity. Any questions, feel free to ask, and go to my photo album here

Oil Cooler fabrication and install album | Ttschwing | Fotki.com for more info, parts list, sources and pics.

If you found this helpful, shoot me some REP points too!....Stay cool....

WINTER UPDATE:

Since this install the weather has gotten cooler. Due to the way the Mocal Thermostatic plate works, the cooler is always in the system and receives flow no matter what the temp. It does not magically open at 180 degrees for a variety of reasons. See the Over-Cooling discussion here:

Over-Cooling Solutions

From Mocal:

Quote:

Mocal oil thermostats are designed to regulate oil flow

through cooling devices until optimal (minimum)

temperatures are reached. Cold oil enters the

thermostat and is bypassed through the center of the

unit returning to engine (figure 1). During warm-up

the thermostat never closes off oil flow to the cooler,

rather, it offers a less restrictive path for the oil to flow*

allowing the cooler to acclimate to system

temperature. As oil warms to 180 degrees (200 in high

temp versions) the operating "waxstat" closes the

bypass permitting full flow to cooler (figure 2).

*percentage of oil bypass can vary up to the point

where the bypass is closed and full flow to the cooler

is achieved.

|

Because of this, you may find, with a normally sized cooler, an inability to get the oil temps up to 180 degrees. There are a few solutions to this, one of which is to make an easily removable cover to reduce air flow through the cooler. I've found this works well and the temps can be brought up to 180 pretty easily even in 30 degree temps. The fab is easy and there are pics in my cooler photo album...

http://public.fotki.com/ttschwing/37...oler-fabricat/

Adjust the size of the cover depending on the winter temps in your area..