Review & Pics:

My mechanic and I installed the Stillen Headers yesterday afternoon/evening. This completes my intake & exhaust setup, as I already had the Stillen cat-back, Berk HFCs, and Stillen G3 intakes installed prior to this. Total install time for the headers was 6 hours (not counting the 3 hours my mechanic took to wrap my headers prior to the install). All in all, it wasn't nearly as bad as we thought it would be, although I'm sure it helped that he's an actual mechanic with an extensive set of tools (i.e., I'd have been screwed if I attempted this on my own; I have a lot of tools, but nowhere near the selection that he has!).

I went with the ceramic coated headers, and even though they are coated, I decided to go ahead and have them wrapped anyway, just to maximize the heat retention (which maximizes exhaust efficiency). For the header wrap, I went with Thermo-Tec's Gen 2 Copper wrap, which is pre-coated with a copper coating, thus eliminating the need to spray them with high-temp coating after wrapping.

Here are the headers, all wrapped and ready to go:

Here's the stock header on the passenger side after the heat shield has been removed (notice the lovely splotch of white paint they put on at the factory; it looks like bird poop):

Close-up view showing O2 sensor and connection flange with cat:

FYI, the passenger side is a lot easier to remove/install, because there are far fewer lines and hoses on the passenger side. My mechanic asked me to pass on the following tip: If you try to do the passenger side and find it difficult, stop right there, don't even attempt the driver's side. Back everything out, and have someone else do it because the passenger side is a piece of cake compared to the driver's side.

Here's the stock header after it was removed. We left the O2 sensor attached, then once we had the entire unit out, we sprayed some penetrating lube into the threads and let it sit for a while. That allowed us to remove the sensor without too much fuss. There was no need for heat or anything like that.

Now, that's not to say that the O2 sensor was easy to get out. It still took a fair amount of muscle, and as you can see below, the threads partially stripped. (My mechanic was able to easily restore the thread using one of his specialty tools.)

Installing the new header was straightforward. The only word of caution here is to make sure you can work by touch. Especially on the driver's side, there are some bolts that you simply can't see. You need to feel for them and work with them without being able to see them.

Here's the passenger side header installed, viewed from the top:

Viewed from the bottom:

The installation was not entirely without issues, and I do have a couple of bones to pick with Stillen. First off, the headers are angled slightly lower than stock, which means that things don't all line up properly when it's time to re-attach the cats and the cat-back. Here are some pics to show you what I mean.

The flange of the HFC no longer lines up perfectly with the cat-back:

Another view:

Lest anyone be tempted to blame this on the Berk HFCs rather than the Stillen headers, let me nip this right in the bud and point out that the flanges lined up just fine when we had the Berk HFCs hooked up to the stock headers. So clearly, it is the new headers that are off.

Beef number two. The bolts that Stillen supplies to connect the header and cat flanges are about a quarter inch too short. Check out how little thread there is once we connected the HFCs to the headers:

Here is a pic showing a Berk-supplied bolt side by side with a Stillen-supplied bolt:

We decided to re-use what Berk bolts we had. The thing is, Berk only supplies 4 bolts instead of 6, because the stock header has a stud attached to it, which means you only need two new bolts per flange (scroll up and look at the pic of the stock header laying on the floor and you'll see what I mean). Well, the Stillen headers aren't set up with a stud attached. It just has 3 holes per flange, which means you need 3 bolts per flange. So we ended up using two Berk bolts per flange, and had no choice but to use one of the shorty Stillen bolts on each flange. Bottom line -- Stillen needs to supply longer bolts.

Edit: I took a look at the stock cats. The flanges on the stock cats are thinner than those on the Berks. So to be fair, Stillen is actually supplying the right size bolts because they're anticipating that their headers are going to be connected to stock cats. In other words, it's not so much that Stillen is supplying short bolts, but more the case that Berk is supplying extra long bolts because they know their flange is thicker. The only problem is that they're only supplying four, not six, because Berk is assuming that their HFCs are being hooked up to stock headers, not aftermarket ones.

Note the shiny new Stillen bolt at the bottom, and the older Berk bolt at the top:

Okay, so back to the issue of connecting the HFCs back up to the cat-back exhaust. As shown above, the angle of the Stillen headers causes the flanges to no longer line up perfectly. What you basically have to do is force them to line up then bolt them together, which is exactly what we did. But guess what issue that exacerbates? Those of you who have been following the experiences of myself and others who have installed the Stillen cat-back (e.g. RCZ, Wstar, Musashi) know that this cat-back has a tendency to contact the middle cross-member. Well, the slightly off-angle of the headers, and resultant need to force the connection between the HFCs and cat-back together, makes it next to impossible to get the cat-back off of the cross-member.

This is the cross-member I'm talking about

:

We settled on the solution that Musashi employed to get the exhaust off the cross-member. We put hose clamps around the rubber hangers and tightened them to compress the hangers and pull the exhaust off the cross-member:

With that, the installation was complete. My butt-dyno driving impression is that these headers have definitely yielded some gains. The engine revs more freely now. Also, I haven't noticed any significant loss of torque in the low-end or mid-range. The power doesn't suddenly come on only at high rpms or anything like that. What I've noticed sound-wise is that with the installation of the headers, my exhaust actually sounds smoother now. Like some of the coarseness that my exhaust note had before is gone. It still sounds aggressive, and it still gets plenty loud at WOT while staying quiet when I'm just cruising. But the whole setup just sounds smoother.

Vid:

I made a new video this morning so you guys can hear what it sounds like from the interior, now that I have the full intake and exhaust setup (the previous interior sound clips I have were made when I had the cat-back and HFCs only).

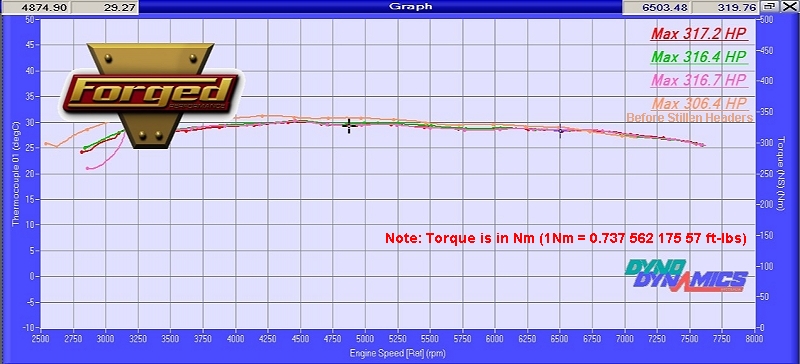

Dyno:

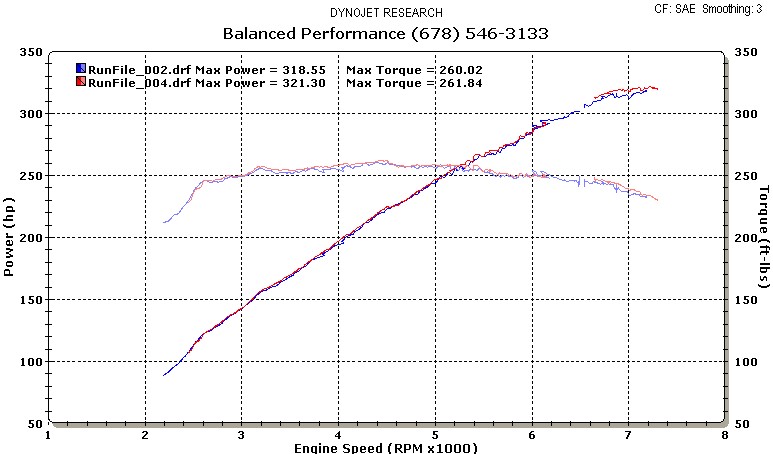

DynoJet Before:

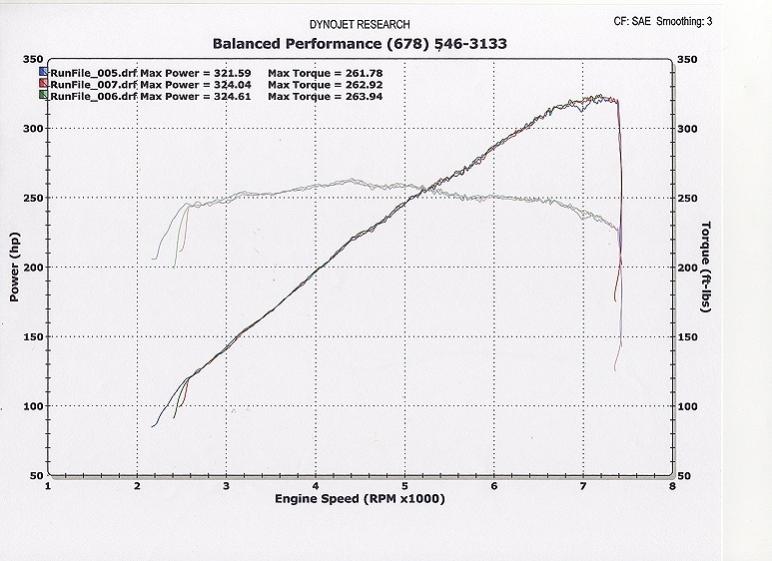

After:

After:

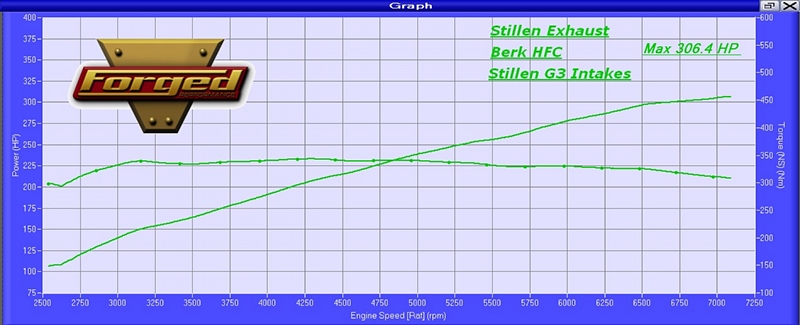

DynoDynamics Before:

DynoDynamics Before:

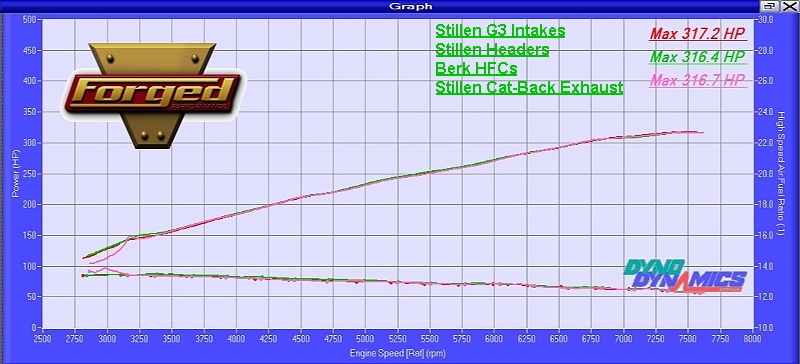

After:

After:

This first graph shows HP and A/F:

This one shows torque:

Don't forget the rep pts if you found this informative/useful!