I started this post on myg37 forums but since G37 and 370z are so similar, I figured it might be beneficial to 370z owners too.

Let me know if anyone has questions.

Most of us have heard about this great turbo kit put together by GTM. Many shops have installed this kit on many G37s with great results. There are even a couple of people that have installed this kit as a DIY. However, I dont think anyone has detailed the installation process on the forums. I wanted to use this thread to journal my installation process as I install the kit in my backyard. 1. to kinda show that a turbo install isnt as complicated as people might think 2. to help anyone out if they want to go with my path.

Before anyone starts to make comments like how I should've let GTM install it, etc etc., let me say a few things. In addition to saving about 3 thousand dollars from the labor, installing this myself is 100 times more fun. I love to get my hands dirty and have always installed performance parts by myself. It always feel so damn good to finish a major project on your own. The car seems to gain more butt dyno WHP when you install parts on your own. :biggthumpup: Plus, its a great learning experience.

Before I start, I want to give special thanks to SAM@GTM for providing excellent parts for a great price. He offered me a before and after dyno, which I will post later.

Also special thanks to Tainui for giving me some really great advice and tips with my install. Tainui is one of the people that installed this kit DIY and has been really helpful to me. Thanks again!

Also wanted to thank TerryCS. In addition to providing the excellent screen protectors and remote covers, Terry answered a bunch of my PMs regarding his GTM turbo kit. Thanks again! :icon38:

My setup:

-Stage 2 .86 A/R turbos

-Internal wastegates

-Powdercoated pipings

-Blitz sbc boost controller

-HKS 1 step colder spark plugs

To answer G37SAM's question, I consider myself to be pretty mechanically inclined. In my old G35, I've stripped the entire interior to dynamat and install a JL audio system. Installed small performance parts such as the spacers and mrev2 (G35 owners would know what i'm talking about

) In the end, a project like this just require you to have the right tools and a lot of patience. :biggthumpup:

Alright on to the pictures:

Here is what the entire kit looks like. Notice how well they are packaged.

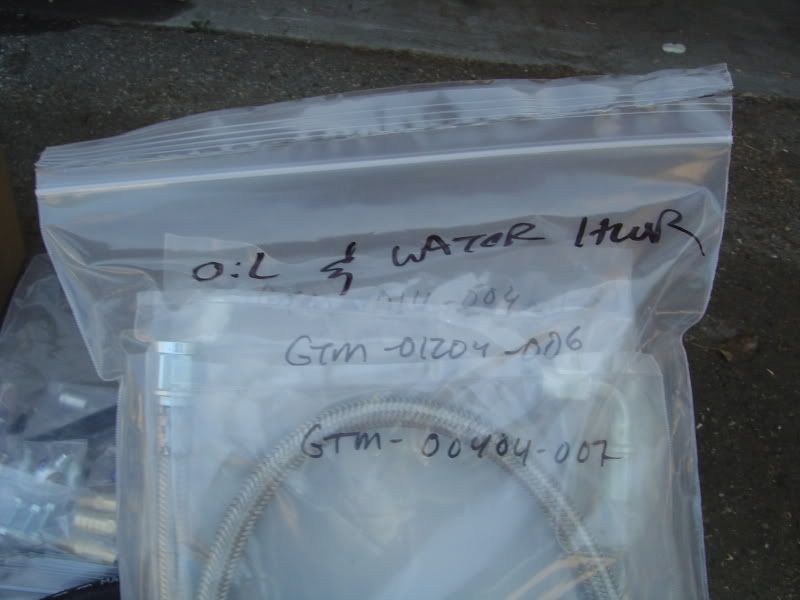

All the bolts, washers, wires, etc are bagged together depending on the component its for. For example, this bag is for the oil and water line parts.

All the couplers and braces are labeled in the bags so its really easy to find what you need.

Check out how each tap is individually wrapped:

I went ahead and got the pipes powdercoated by GTM. I'm really happy with how the pipes look:

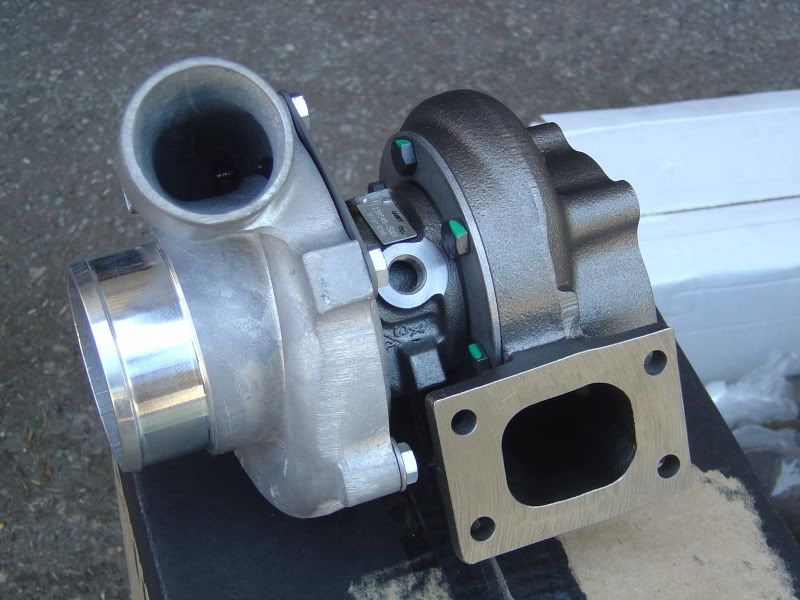

Stage 2 turbos:

So far I'm really happy with the completeness of the GTM kit. The way they packaged this kit will save me many hours of digging thru the boxes to find a bolt or nut. I'll keep updating this thread as I go thru the install each day. :biggthumpup:

Day 1:

I did my install a little different from the order that GTM suggested. First, I did everything that did not require the car to be lifted.

I started off by painting some of the metal parts prone to rust. As recommended by GTM, I painted the spacers, wastegate bracket, and steering linkage:

Then the turbos were prepped:

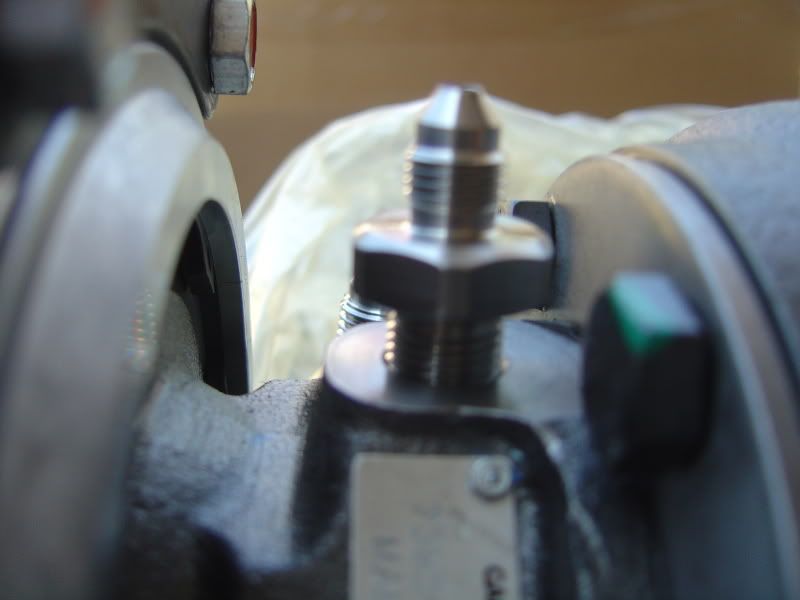

I wont go into all the details, it is outlined very well in the installation manual. But you need to loosen all the bolts on the turbo, lube it, and attach some of the drain and feed taps:

I do have a question about this tap on the passenger side turbo. Is the tap supposed to stick up like this? This is as far as it goes. Maybe Tainui or Sam can chime in?

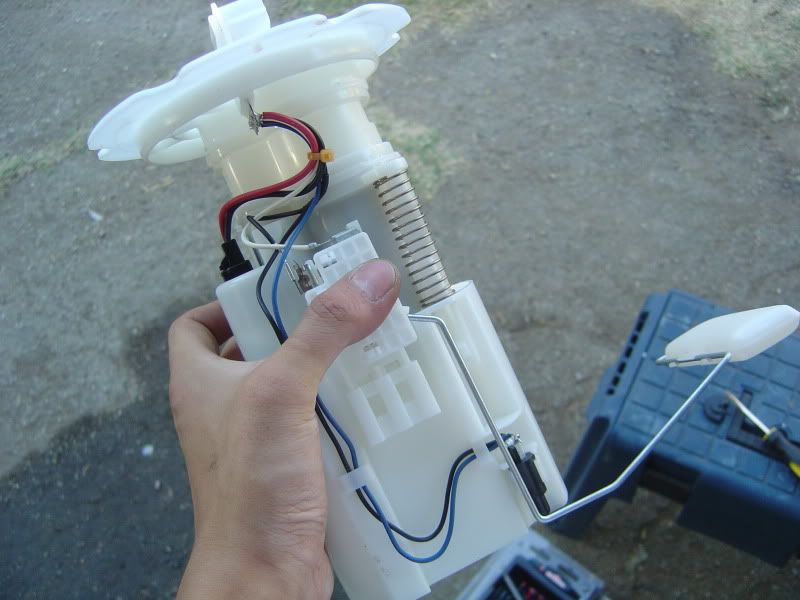

The stock fuel pump is taken out from the back seat. Just use a screw driver and twist the tabs:

Here is a picture of the stock pump next to the new walbro pump:

The walbro pump is longer than the stock one so the tabs on the bottom of the new pump have to be trimmed off to fit in the bucket.

Looks like this after tabs were removed:

Take the fuel filter from the stock pump and replace it on the new one.

You need to drill the jet whirl using a 1/16" drill bit to enlarge the whole for the increased flow. Also need to drill the relief orifice using a 7/64" drill bit:

Put it all back together:

Time to tackle the engine bay to replace the injectors and spark plugs. Here is a picture of my current setup with injen CAI:

Nothing complicated here, just remove all the bolts holding the stock intake manifold and disconnect all the vacuum and water lines. Cover up the intake runners with painter's tape so no debris would enter the heads.

Remove the bolts for the fuel rails and pull the entire thing straight up. Make sure there is no orings stuck in the heads. Stock injectors look like this:

Unplug the harness and remove the clips. Then you can just pull the injectors out. Use the superlube that is provided with the kit and lube up the orings on the new 600cc injectors. Push the side with the brown orings into rails. There is no clips. Push in the stock harness. There is no cutting or soldering of wires.

600CC injectors installed:

Then i went ahead and install the block off plate for the turbo manifold. This hole is usually for externally wastegated setups and the kit provides a block off plate for internally gated setups. I felt it would be easier to put in on now than after mounting it into the heads. You just simply put in the 4 provided studs, place the cover and tighten the nuts:

Do the same thing for the passenger side.

Now's a good time to tap the intake manifold for vacuum hoses. Just drill with a bit and tap with a 27 NPT tap. Apply some sealant and screw in the tap. Here is the driver side:

Passenger side:

Rear tap:

Driver and passenger side taps are going to the blow off valves. The rear one will go to the MAP sensor on the boost controller.

That's all for now! Will update again after i finish working on it today.

Day 2:

Today was a slow install day. I found out what others meant when they say headers are hard to remove. Anyways, I started off installing the new HKS spark plugs. With the intake manifold off, the install was a cinch. The spark plugs are 14mm and you'll need an extension to reach down to them. Just swap them out and torque them down to factory spec.

Here is a side by side view of stock and HKS sparks.

Now onto the headers.

The passenger side was not too bad. The heat shield came out pretty easily after removing 3 bolts. Then I removed the oxygen sensor from underneath the car. I had them soaked in PB Blaster overnight, so they came out very easily and cleanly. There are 6 bolts holding the header in, 3 on top and 3 on bottom. Using different ratchet bits and extensions, I go all of the bolts out. There is plenty of room to work with. Let the header fall down thru the bottom.

The driver side header is a major PITA. There is hardly any room to work with. The hardest part for me was actually getting the heat shield out. The bolts can be removed easily but there is not enough gap for the shield to be pulled out. It took me an hour just rotating and banging on the shield to finally get it out. The rest is not too bad. Again using different bits and extensions, slowly remove the six bolts and let the header come out from the bottom.

Here is a picture of passenger side with the header removed.

In order to fit the new turbo manifold, 2 of the studs have to be removed from the passenger side. You use 4 nuts to bolt down the front of the header and 2 allen bolts to fasten the rear. The two allen bolts screws into a different location than the stock stud.

As I found out, the new location is not threaded and you have to tap it yourself. You need a 10m x 1.25 tap.

Finally, I was able fasten the passenger turbo manifold.

Here is a picture of the driver side with the header removed. I have no attached the manifold yet. Will tackle that tomorrow.

And here is a picture of the turbo fully assembled with the internal wastegates:

Day 3-4

Day 3-4

Update:

I have not really been able to work on install during the weekdays. I only have about 2-3 hours every night after work to do some small things. In the last couple of days I was able to get the driver side turbo manifold mounted and oil return fittings tapped.

Driver side manifold install was another major PITA. First of all, you need to relocate 2 studs, which mean you need to tap another 2 threads. The top row studs need to be taken out and replaced with shorter studs. But those are the easy parts. The gap between the engine and fender wall is tiny and the manifold is big. Even with the small studs, the manifold still has trouble fitting into the studs and the side rubs against the fender wall foam. So I had to use a rubber mallet and help convince the manifold to go in the studs. After it goes fully into the studs, the side no longer rubs against the fender wall. The nuts are also harder to tighten because of the lack of space. But after 5 cuts or so on my hands, the manifold is mounted. Make sure you don’t forget to put in the gasket first. You don’t want to have to mount it twice.

The oil pan tap was much easier than I expected. However, you need to have the right parts before starting. We need to tap 2 holes for the oil drain. The size of the thread is brass fitting 3/8 NPT. This was a very hard tap size to locate. For some reason, brass fitting sizes are different from normal fittings. Even though it says its 3/8”, the fitting is actually around 5/8”. I was finally able to locate this part at Harbor Freight Tools. You also need an angled drill. The pan is small so you won’t be able to fit a regular drill.

First of all, you need to drill a small hole and increase the size until 37/64” drill bit. However, the biggest drill bit I had was a 1/2”. So I used a dremel to enlarge the hole slightly. Be careful when you do this. If you make the hole too big, the fitting might fit loosely and you’ll have a leak.

Splitting the pan is fairly simple. Use a 10mm ratchet and remove all the bolts. Then use a small thin flat head screw driver and separate the pan. It should look something like this:

Then you need to remove the oil funnel thing by removing 2 x 12mm bolts. Then you can mark your location and start drilling with a small drill bit first and then enlarge it. It should look something like this:

Make sure you tap the thread from the outside in because you want the fitting to fit from the outside. Here are pictures of the driver side installed:

Then just clean off all the metal debris, reinstall the oil funnel thing, add gasket to the oil pan and bolt it shut.

That’s all for now!