WOT IN PROCRASTINATION!?

okay, but really though, time to update the build thread forreal this time... I just REALLLLLYYYY HATEEE messing with photobucket. JFC there are more ads on this site than a got-dam super bowl!

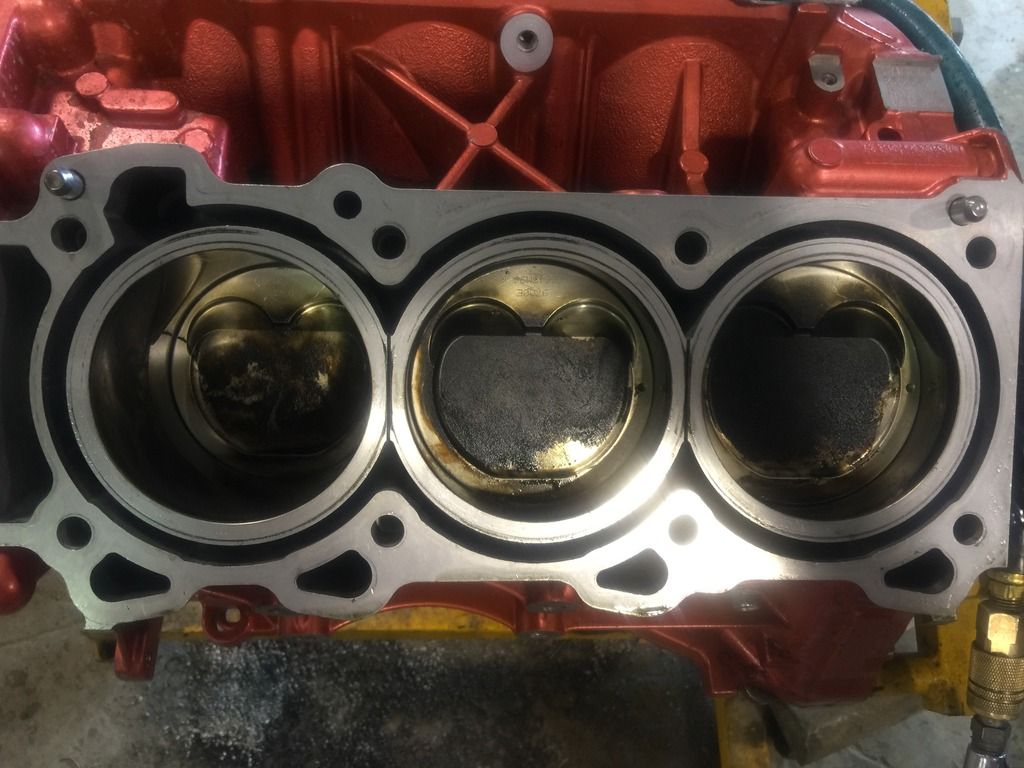

So middle of last spring the ole VHR that could suffered from an oil control ring failure. Unfortunate, but as they say: "you pay to play"

. for those of you that are new to this game....

http://vid1044.photobucket.com/album...pszhccki9l.mp4

FYI you shouldn't be able to dump oil out of your turbo manifold.. that's usually a pretty tell-tale sign of ring failure XD

Anyway, so as with the new season came a new idea; several actually.

I should've known how the next 9 months were going to go at that time. This car has been nothing short of problematic at times; most self inflicted. All part of the learning curve. I have allowed my pocket book to test almost every corner of this engine with the final hurdle being the open deck design. The "oh so scary" TRUE reliability nightmare. At what point do we

really need to go sleeves or block guards? Or are these people diving in $1700... $3000 for a piece of mind they will likely never need. If the point should come, I think I'm going to take a different rout(a pioneering route for this platform of sorts) but the test of time will give me the answer for that. Blah Blah... enough with the rambling on this for now back to the build!

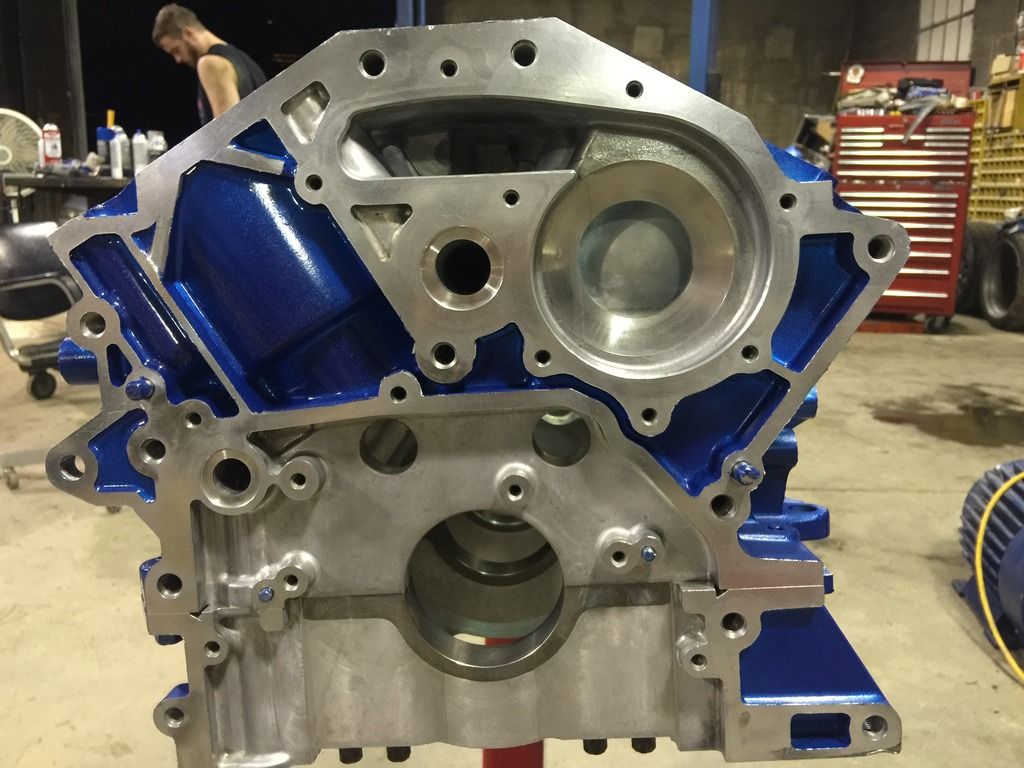

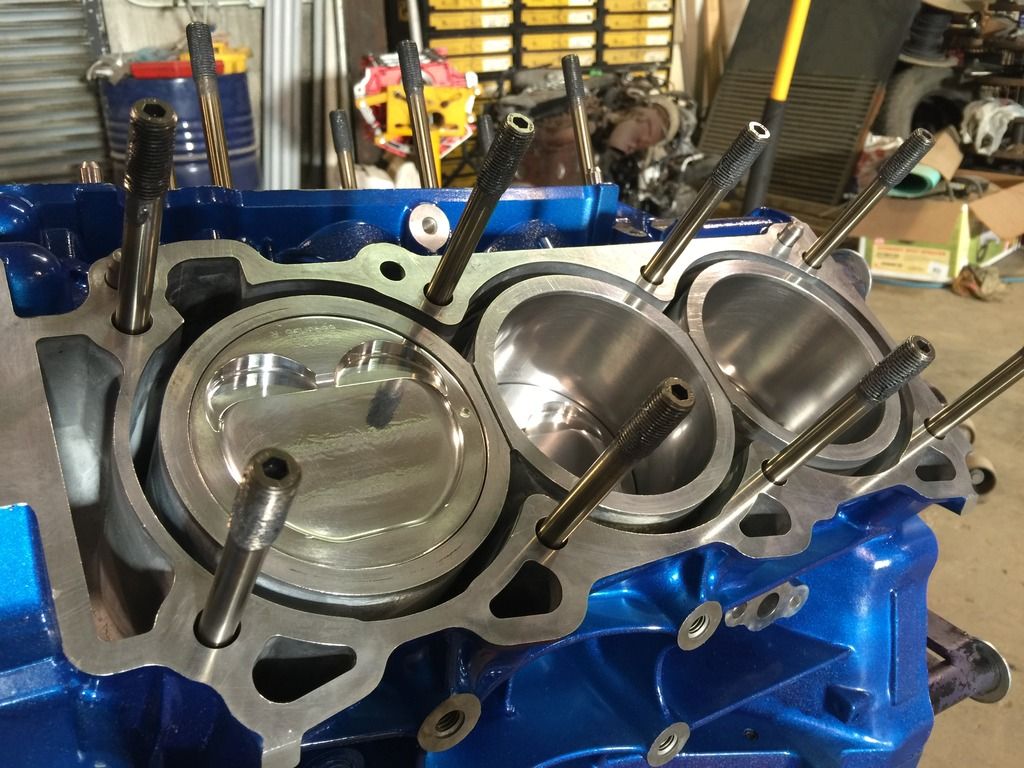

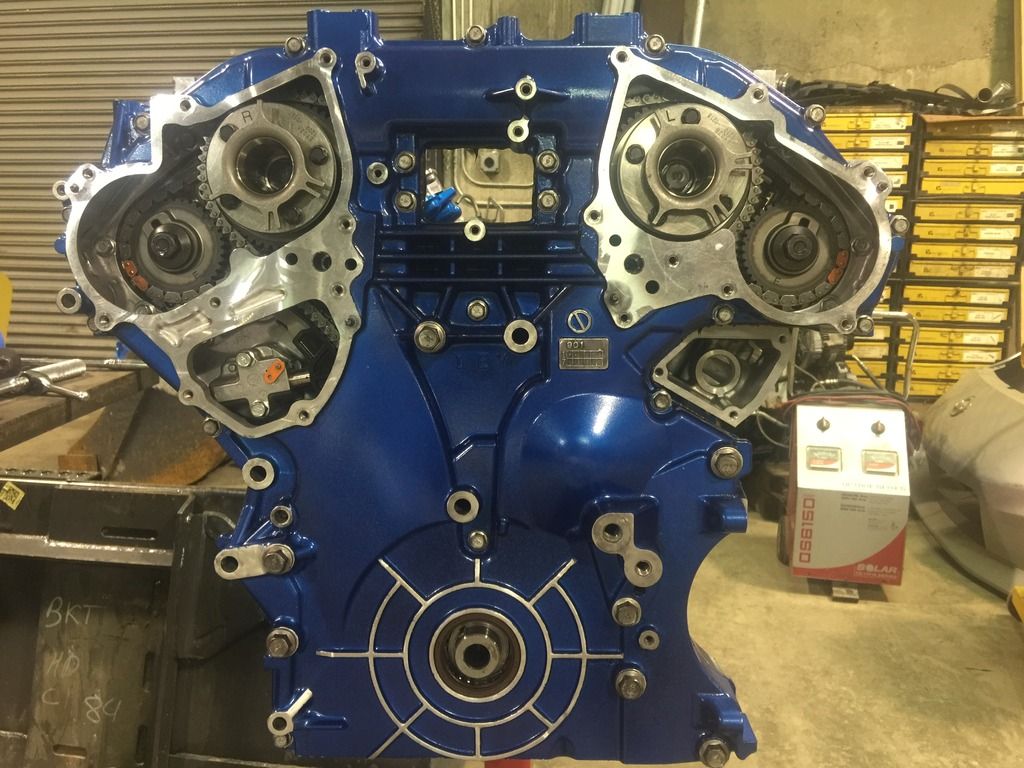

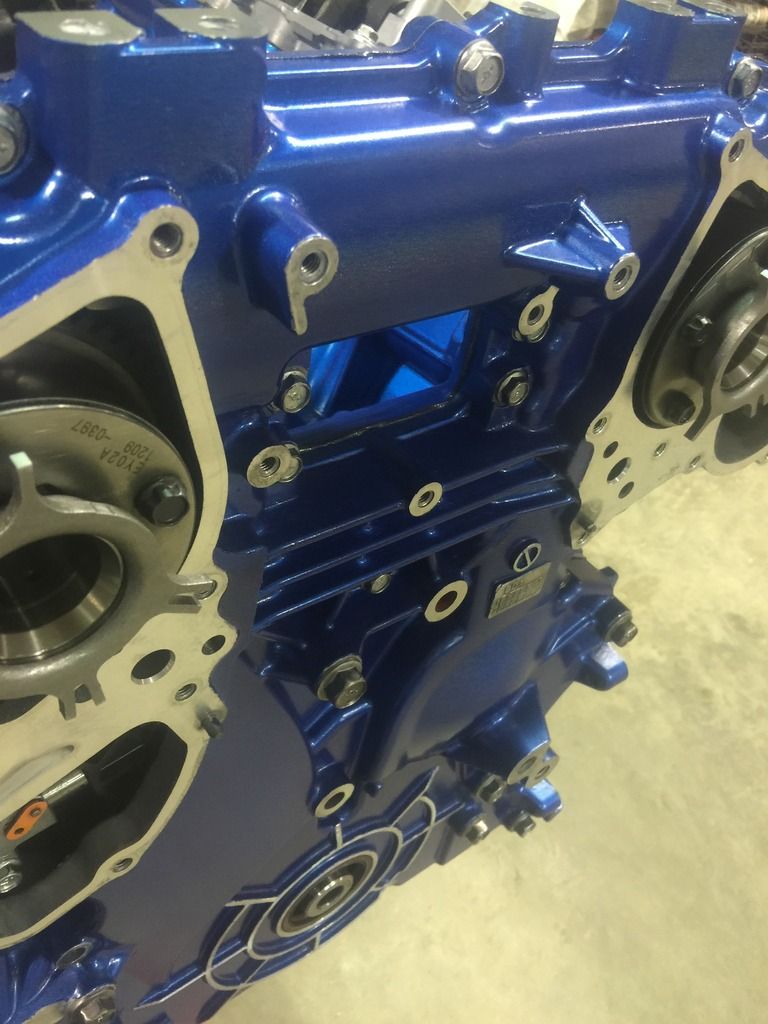

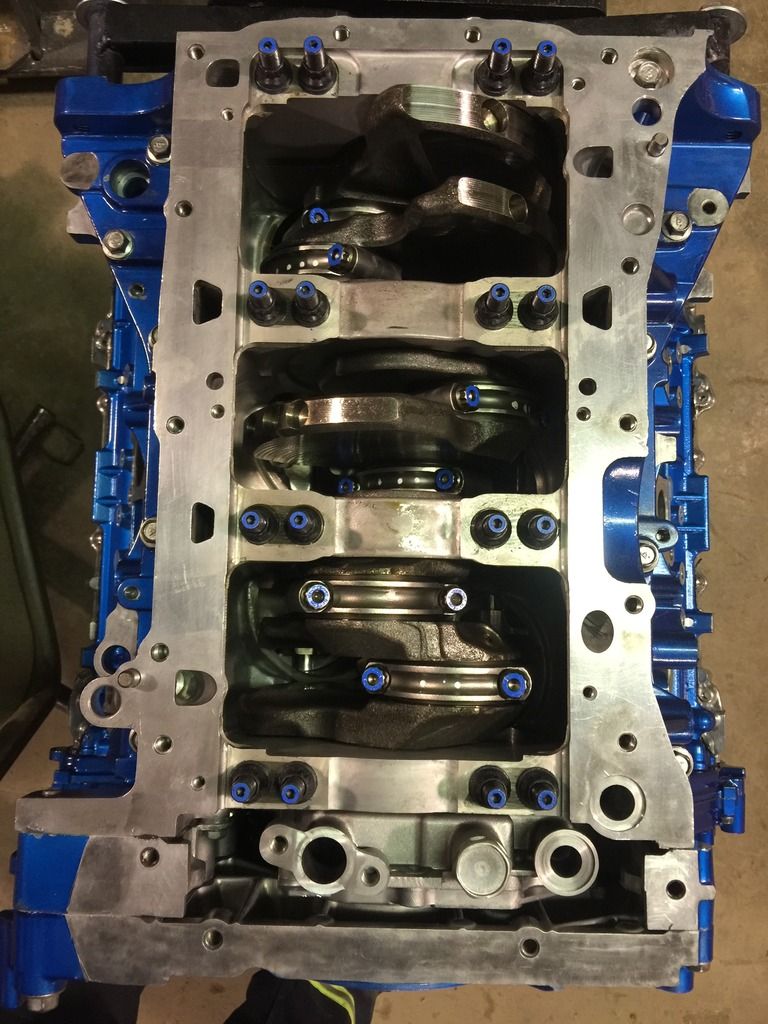

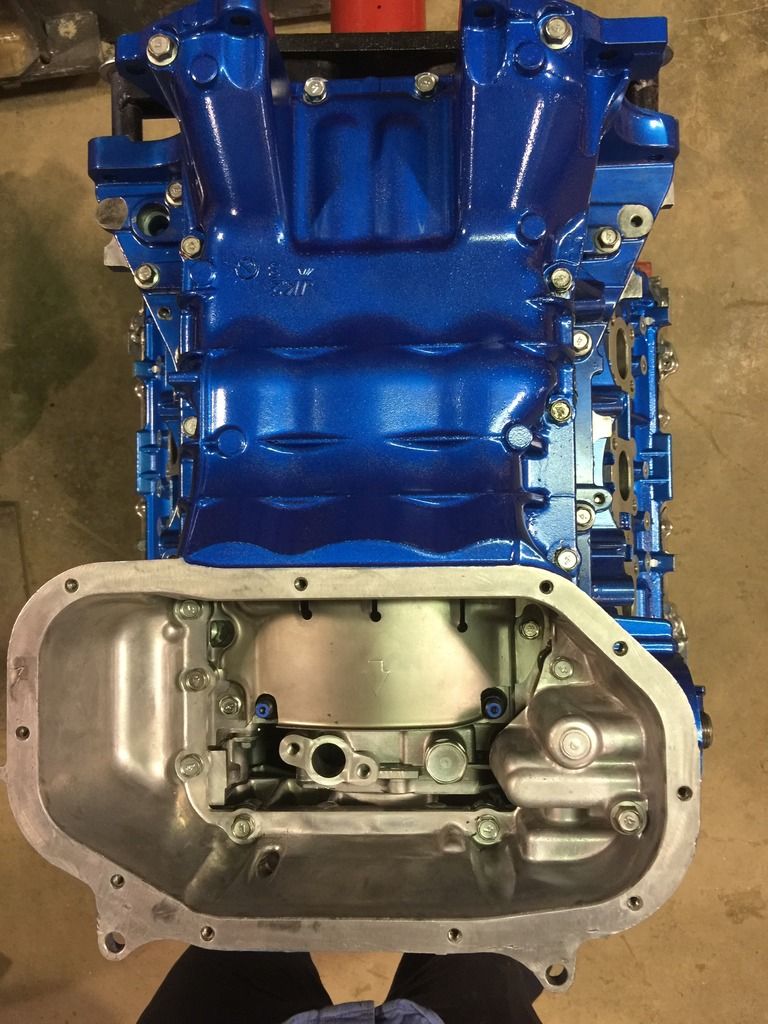

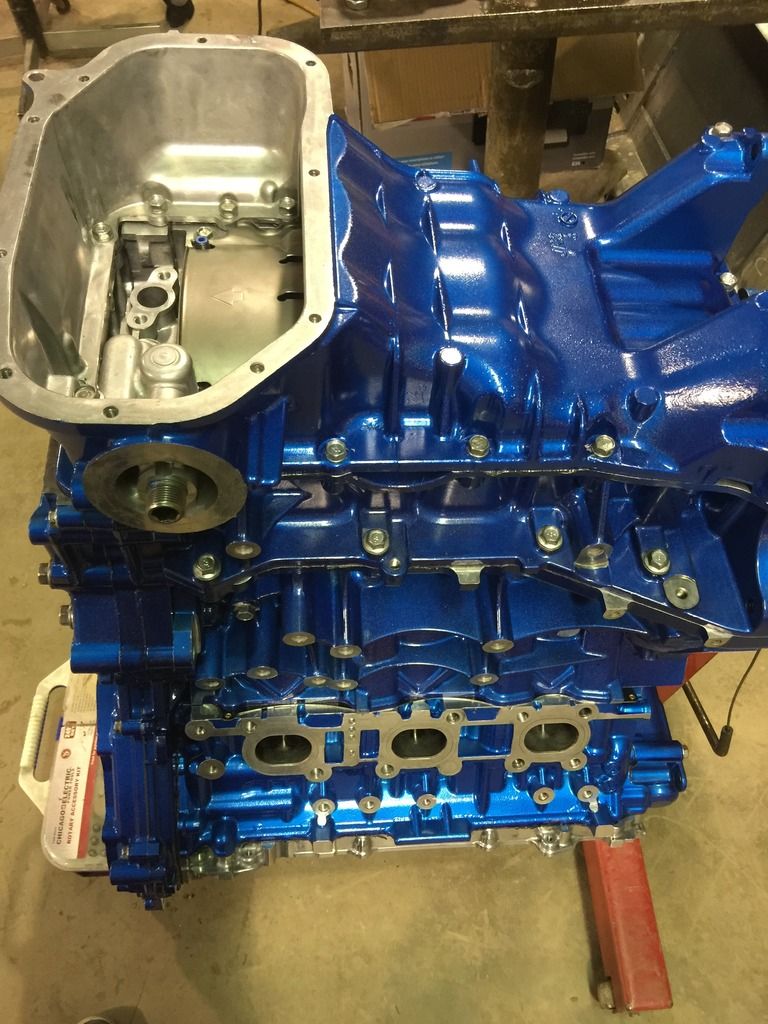

It was time for a change of heart... Betsy's heart that is; and you could say she had me "feeling a little blue".

damn I'm so "punny"

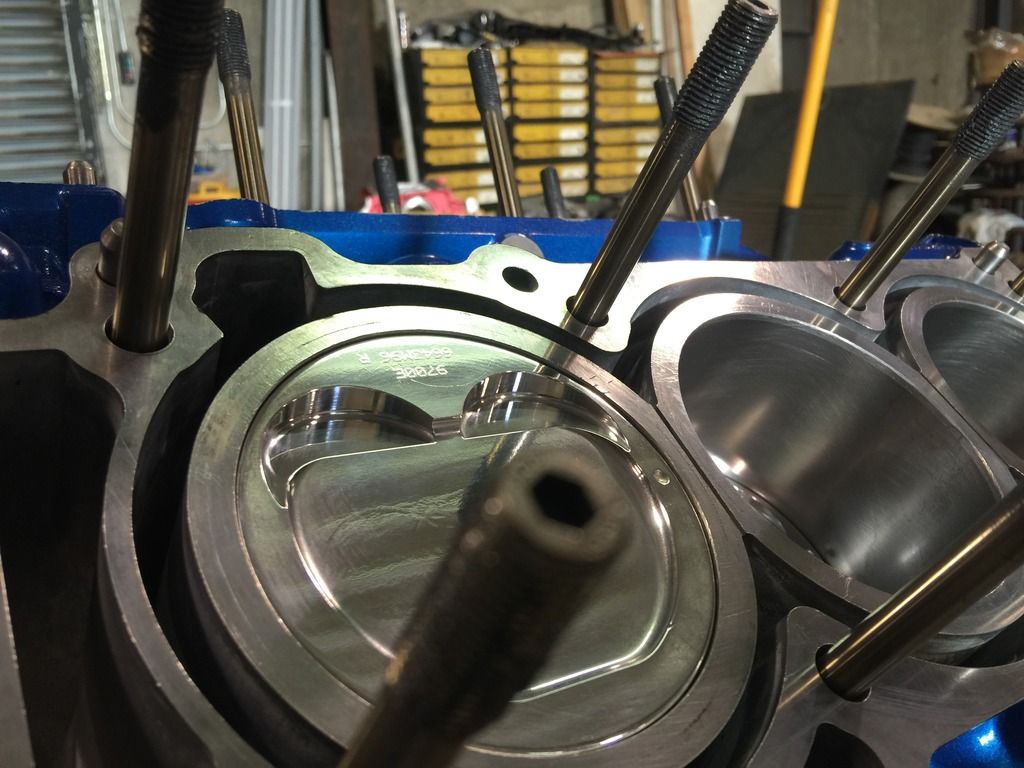

as usual... no shortage of OCD bringing attention to detail here folks. Went a littleeeee off the deep end and decided to polish the piston crowns as well. results were fantastic though I must say! XD

maybe Wiseco will give me a hire on opportunity

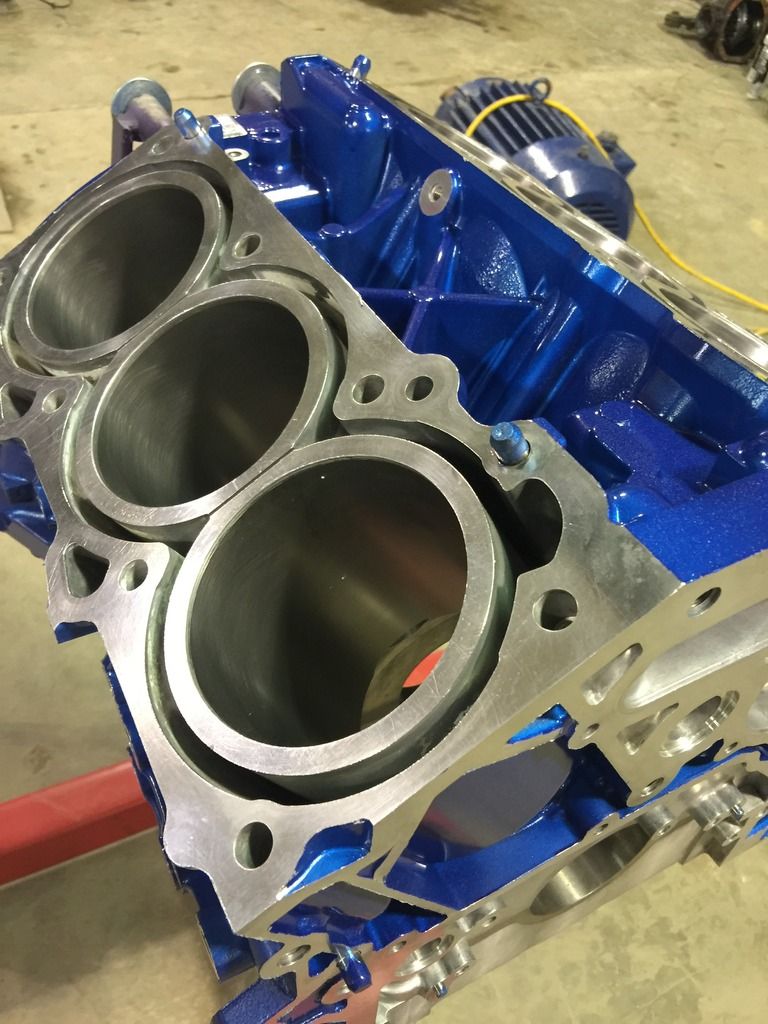

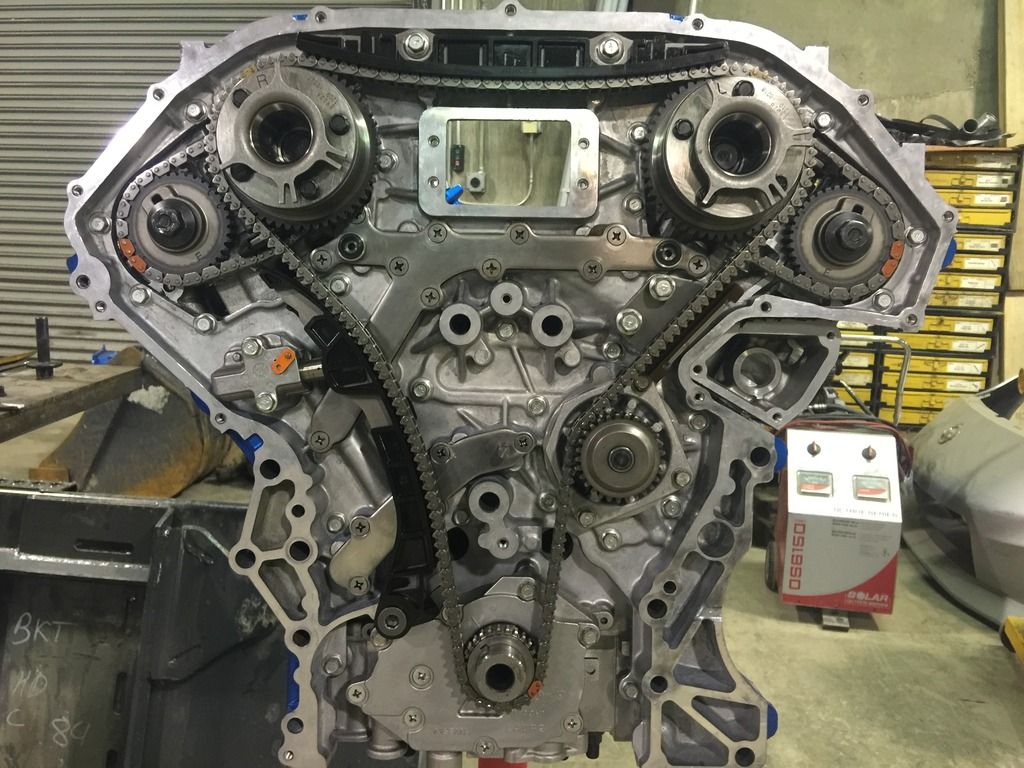

you guys have seen all of this before I'm certain, but for the sake of watching the rest of the blueberry grow :P...

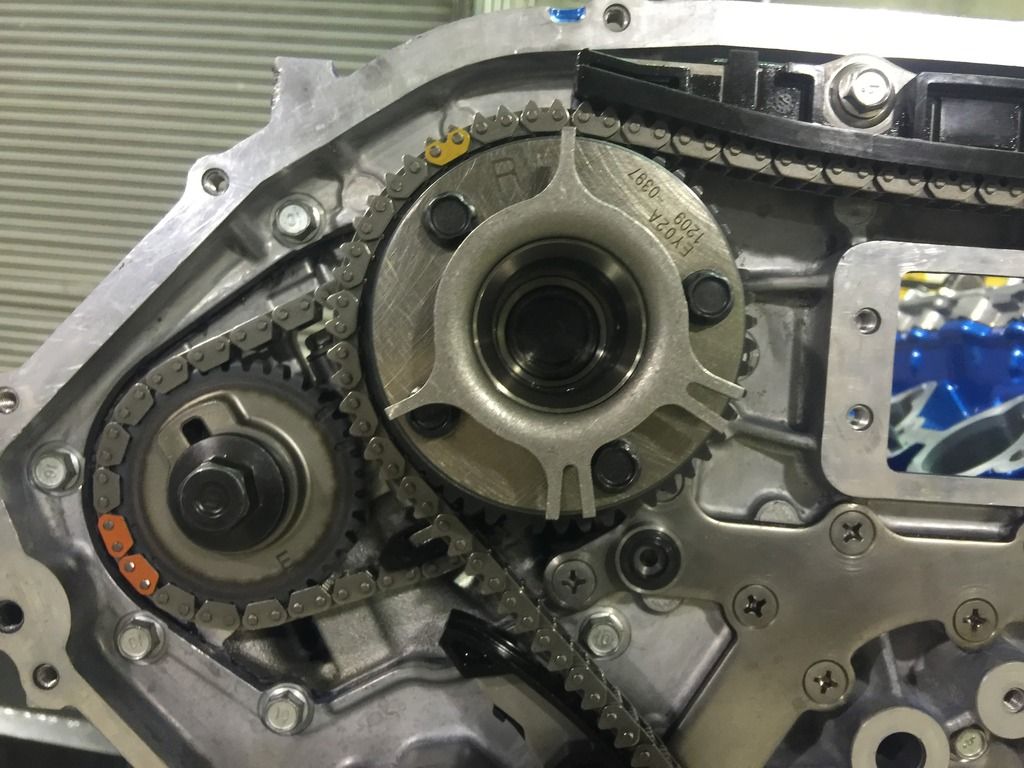

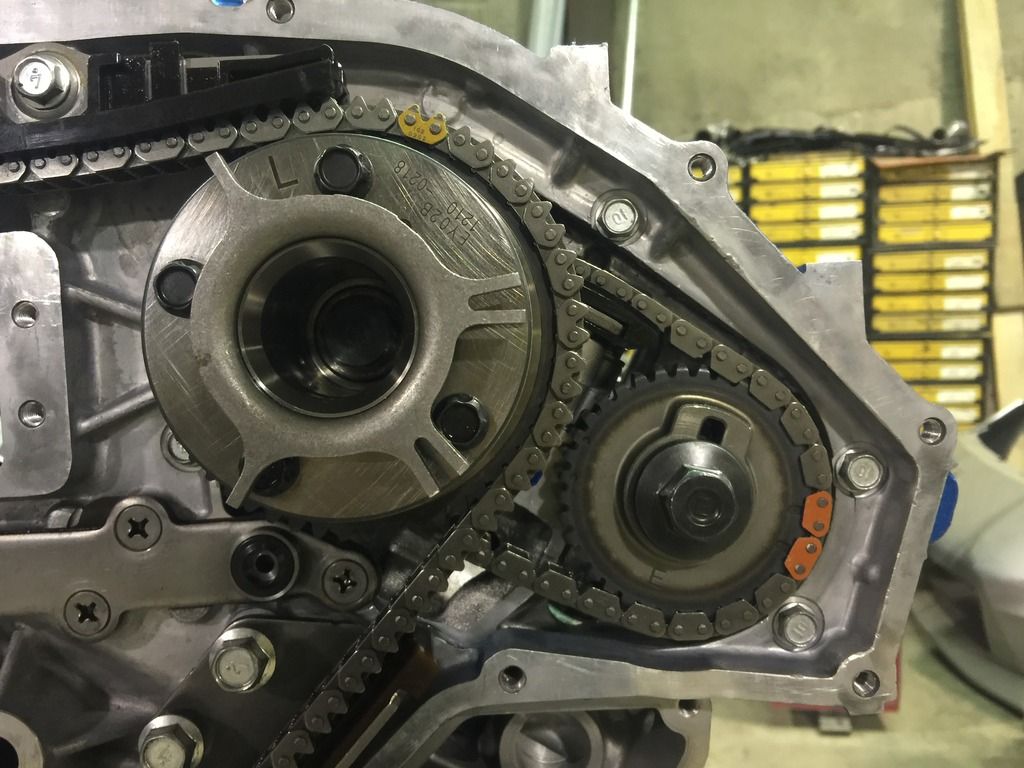

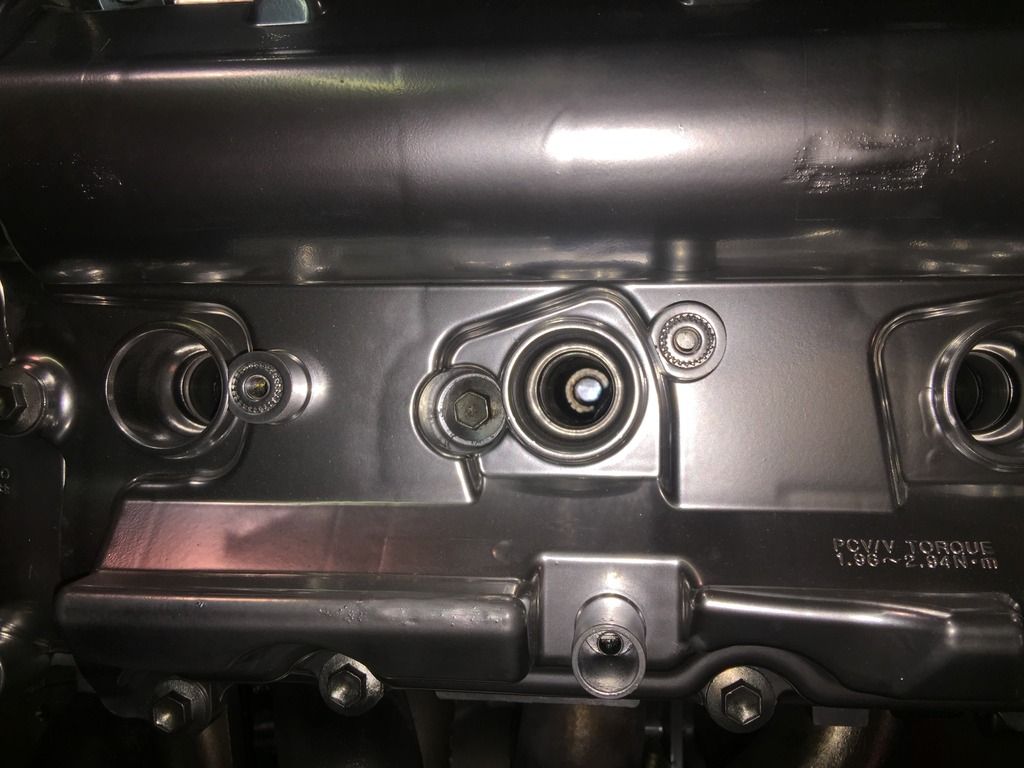

This time I decided to do a little better job documenting the timing arrangement as a reference for anyone in the future.

Its VERY important to understand that when building an engine everything is referenced as looking at the crank pulley.

With that said R-Right(Passenger) Side is aligned to the "Circles"

L-Left(Driver) Side is aligned to the "Ovals"

Intake Cam-Crank timing is a little more tricky crankshaft MUST be placed in TDC and not a single tooth off of the timing circles at any location.

Yes, it is a pearlescent, for those curious. Couldn't keep things THAT simple

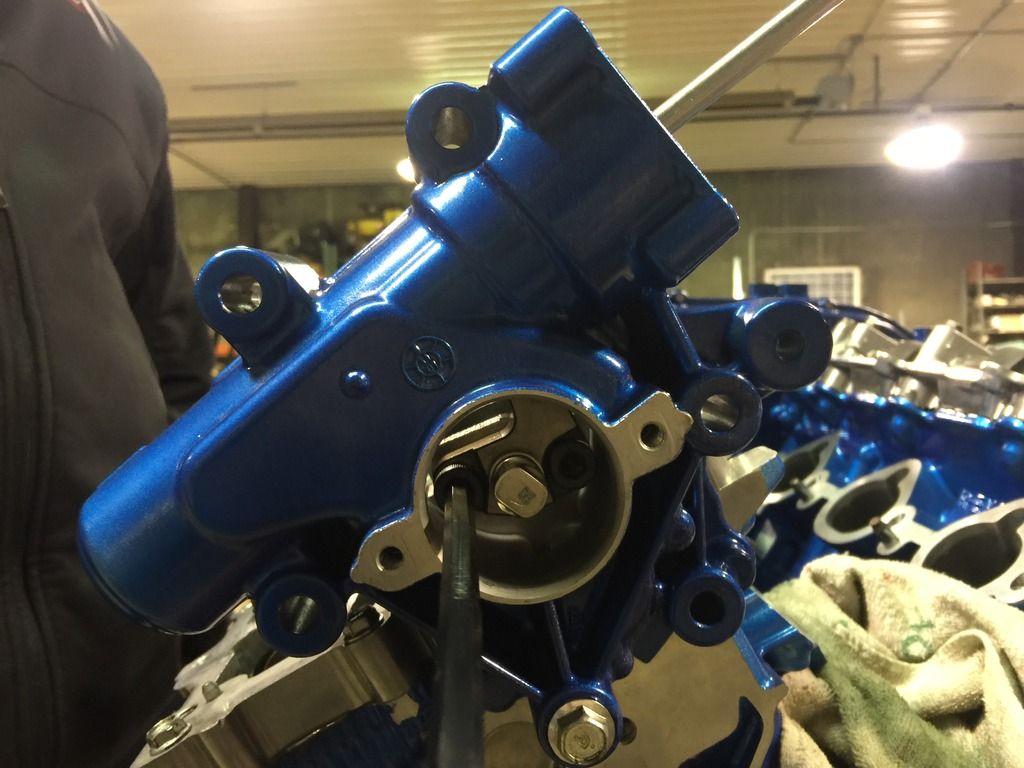

this time I decided to paint the actuator housings as well. which required tearing them down... in which doing so meant............ NO MORE PRELOAD ON THE ACTUATOR SPRING

but don't worry. I once again did all of the hard work to reassemble the oh so scary VVEL assembly. Most people would buy into the bs that you have to buy new actuators from Nissan in a situation like this

bold or not, I called their bluff.

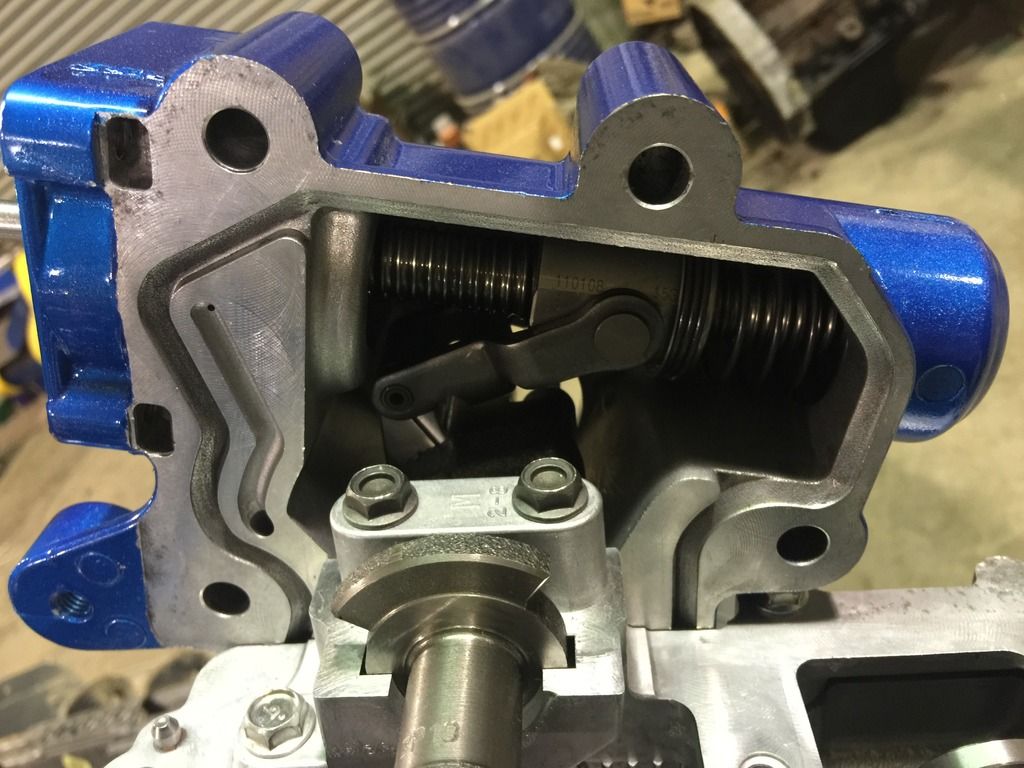

place the VVEL cradles back on the car and use a digital level gauge on a consistent flat spot on the eccentric cam. With a 7/8" wrench adjust the eccentric cam itself to 5.5*. WITHOUT BUMPING THE ASSEMBLY place the actuator assembly onto the rear of the head(don't install your gasket sealant just yet), and once again, CAREFULLY place the magnetized actuator to the rear of the eccentric cam. Like so. (Its also a smart idea to install on of the housing bolts to keep the assembly from falling off the back of your head before its aligned and fastened.

You'll see I stress the careful multiple times because you will really begin to hate yourself for being so rough after having to start the process over 4 or 5 times when you bump the gauge out of calibration. It only takes a slight "jiggle" of the engine stand to do so, and while sure I may make this task sound less daunting than it really is

make no mistake here this isn't a part you want to half-@ss...

Now if you were paying attention when removing the actuator motors from the assembly you would realize that holding the end of the motor connected to the actuator spring is a square "collar" of sorts. In the real world we refer to those as a coupler. conveniently enough this collar houses a 1/4 drive extension WONDERFULLY. Place the coupler on the end of a 3-6" 1/4 extension attached to a 1/4" drive ratchet and set it to the "On" position. carefully rotate the ratchet until the actuator preload is set aligning the holes on the actuator to the threads in the rear of the eccentric cam; such that you can now properly reinstall the two 6mm Allen bolts in the rear of the eccentric cam. There is no "messing" this part up they either thread in or they don't. if they don't slide right into place then you have too much, or too little preload. simple as that. the picture above has this alignment part already complete.

Here is one of the whole process though capturing the 1/4" drive ratchet being used to set the preload while I re-home the Allen bolts. Don't mind my brothers chubby belly photobomb. He watches in amazement as this whole "VVEL" thing baffles 2JZ owners apparently

and here's your finished product! now remove the 1/4" ratchet and extension leaving the coupler in place, and align the drive shaft on the electric motor to the coupler. fasten the motor back to the actuator assembly with the 4 5mm Allen bolts(be sure not to forget to reinstall the gasket) and viola! at this point you're safe to remove the actuator from the cam for gasket sealant and proper reassembly.

Yes, that is those pistons I shined up GLEAMING through the spark plug hole

I'm going to call her quits there for tonight folks its 2:45am and I gotta work in 4 hours lol. Should get around doing another decent write up tomorrow!

Thought about sliding over to the "meaty tire thread" and dropping some bombs to show the meaning of, but nahhhh. I think ill keep the imaginations right. here.

night folks!