Quote:

Originally Posted by Nithmo

Actually, that's not true at all. You induce less stress on the transmission components- especially the synchros, by shifting down sequentially. It's much harder on the synchros to go from, say, 4th to 2nd, as opposed to going 4th-3rd-2nd. What that does is allows the transmission speed to stay in line with the vehicle speed. I know I'm not explaining this 100%, but suffice to say, what you're suggesting is that normal shifting of gears will result in transmission failure. That's not true. The car prefers it.

|

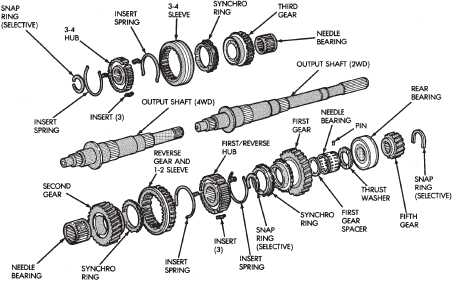

The syncrho is just there to slow things down to to help the slider engage the gears. It has friction material on it for a reason. I see no reason to wear the friction material on other gears unnecessarily, not to mention those gears sliders unnecessarily. Especially as the syncros are cheap, the sliders are the expensive parts generally in every transmission I've rebuilt.

What I'm referring to a slider, is the sleeve here (this isn't from a 370z transmission, just images I had handy, It's from a Jeep transmission):

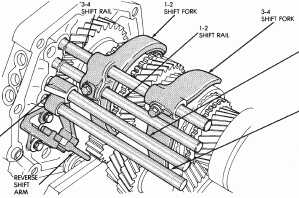

It would be what the shift fork actually is moving to engage the gears:

So while you maybe trying to keep things spinning the same speed and help things line up, I'm still of the opinion you're placing unnecessary wear on components that didn't need to be enaged in my opinion.

To each their own though. It's likely it may not matter one way or the other, and the transmission will live "long enough" either way I guess.