I wanted to provide you all with some additional background info concerning this project.

We ran into some issues with the intake manifold, which took us some time to overcome. Many of these delays are attributed to the casting process. The first limited batch of intake manifolds we originally received for testing purposes were terribly inconsistent in terms of their fit and finish. They did not live up to AAM Competition’s quality standards. The cast manufacturer had told us that this particular mold was extremely difficult to work with. Our engineer made some minor adjustments to the CAD design of the manifold to make the casting process more efficient and accurate. In order to implement these changes, the manufacturer then had to create an entirely new mold.

Once the new mold was completed, a new limited run of manifolds were put into production. After the revised manifolds had arrived, we could resume evaluating the units. These manifolds were MUCH more consistent, which definitely made our additional effort and investment worthwhile. During quality analysis, we quickly discovered that many of these intakes were not holding pressure. Ouch! ….. yet another hurdle to deal with. We promptly coordinated with the casting manufacturer to discuss this problem, ensure that a proper solution was put into place for production, and ordered yet ANOTHER set of intake manifolds.

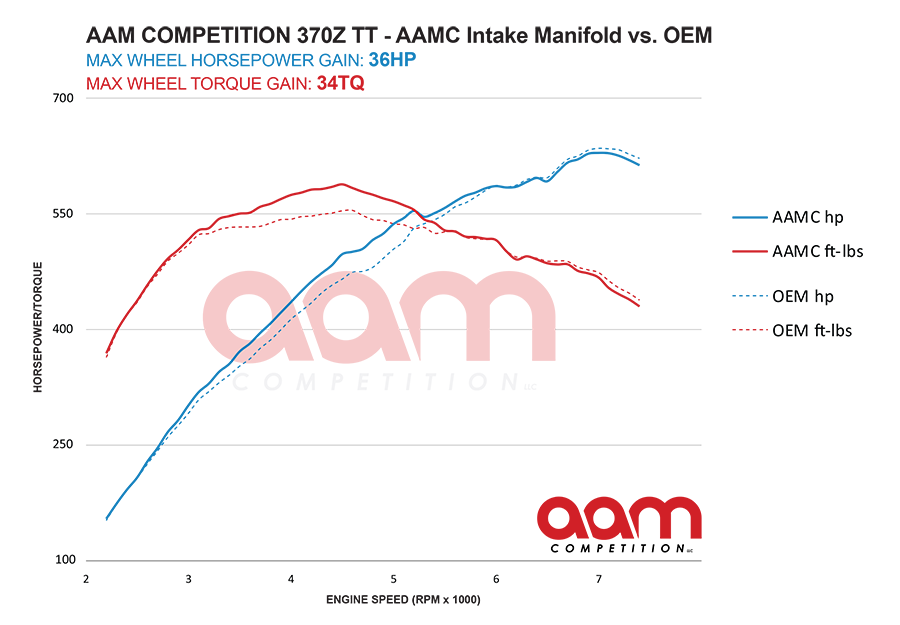

All of that said, we’ve FINALLY received a limited run of manifolds which are not plagued with the prior production faults. With this batch, we were able to further review and analyze the units as we intended them to be. Dyno testing on a high power, high boost twin turbo 370Z (the type of application we designed the manifold around) proved a peak gain of 36whp/34ft. lbs. in the midrange! We are very pleased with these results, and look forward to pushing the manifolds even harder to see how they perform.

Although we do not anticipate significant gains for NA applications, we will be performing NA dyno testing as well. The AAM Competition VQ37 Performance Intake Manifold was specifically designed with high power forced induction in mind. For naturally aspirated vehicles, this will be primarily an aesthetic upgrade, with the added benefit of being much more durable than the OEM plastic manifold. I'll be sure to post these results here as soon as they are available.