Most of us that are boosted (and probably some CAI) had to delete our washer bottles and have just been living with it.

I've been boosted for a while now and for the most part, I haven't really missed the washer... but from time to time when you really need it, not having it can be annoying. So I made my own... hope this helps someone!

Background:

Conceptually the washer reservoir is a pretty simple thing. It's just a vented container with a hole for the pump, and optionally a level sensor. It can be as simple as grabbing an empty container (water bottles...detergent bottle, etc) and installing the pump into it.

Requirements:

1) Stock location - There is still a good bit of empty space in there and I want to avoid cutting the factory harness to relocate the pump.

2) Keep the level sensor - because.. why not? I'm always trying to keep my car as factory feeling as possible despite all the mods.

3) Be able to fill from the top of the engine compartment.

What you need: (Updated for v2 filler neck)

Level sensor

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

Pump

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

1x 3" PVC pipe, about 8.5"

1x 3/4" x 3/4" Male NPT hose barb

1x 3/4" x 3/4" Female NPT hose barb

1x 3/4" NPT Plug

2x hose clamps

2x 3" test/knockout caps

24" 3/4" ID flexible tubing

Aluminum or Steel for making brackets (mine was 3/4" x 1/8")

PVC Cement

Teflon tape

Parts list if building with larger v1 filler neck:

Here is a pic showing the difference between the v2 (smaller) filler neck vs the v1.

Costs: ~$25 for the PVC stuff (can be found at lowes). ~$30 for the new pump and sensor (or just rip out your OE ones). I had the aluminum laying around.

(Note, picture reflects parts for v1 filler neck)

Bottle:

Bottle:

Started out by making a bracket to hold the bottle.. it uses a leftover mount for the OEM bottle.

Here is how I make my brackets.. clamp it down and hit it with a hammer.

Test fit a piece of pipe to make sure it doesn't interfere with the bumper:

Unfortunately it hits the DRL. pre-'13 guys might be able to use this large of a bottle.

Had to cut the pipe and bracket a little shorter.

Test fit with the bumper again - all good!

Resulting size of bracket:

And pipe:

Bore a 1" hole in the pipe close to the edge, ensuring it isn't so close it will interfere with the test cap. If you have a 3/4" NPT tap, thread the hole. I didn't so I just wrapped the barb threads with teflon tape and forcibly threaded it in a few turns. I had originally planned to seal around it with epoxy, but to my surprise this turned out to be water tight.

I used a step bit for all the drilling in this DIY.

Cement in one of the test caps on the barbed end. Make sure you thoroughly scuff and clean the PVC mating surfaces before bonding to ensure a watertight seal. After it cures you can fill in some water temporarily to check for leaks in the cap or around the barb.

Mark where you want to attach the pump (scroll down to see how mine finished out) and bore a 13/16" hole.

Bore a 1 1/4" hole in the other test cap and fit the level sensor. Cement it onto the other end of the 3" pipe.

v2 Filler Neck:

v2 Filler Neck:

The v2 neck is much simpler, smaller, and frees up the airbox mount for use with something else (like an oil catch can or something). It consists completely of a 3/4" barb with female 3/4" NPT theaded end and a 3/4" NPT plug. Drill a small hole in the plug for venting.

Here is the v2 neck (smaller) in comparison to the v1.

Make a bracket.. needs to be a little larger to clear the rubber sealing trim for the hood (will be obvious in installed pic):

Bracket installed:

Filler in place - I just ziptied it to the bracket to hold it in place:

Instructions if making the larger v1 Filler neck:

Instructions if making the larger v1 Filler neck:

( Click to show/hide )Filler Neck:

I planned to paint my filler neck so I sanded/filed and filled the 1 1/2" parts to remove the molding imperfections and raised lettering.

Use PVC cement to install the reducer bushing into the coupler. Make sure you scuff and clean the PVC mating surfaces well to ensure a good seal. Install one of the hose barbs into the bushing with teflon tape.

Make up a bracket for the filler neck..

The filler neck is going to where the passenger air box used to be using an existing mounting point (scroll to the end to see). Mark up where you want the bracket on the filler neck and epoxy it in place. Drill a vent hole in the plug (which will be the cap).

Couple coats of paint (I went with texture black)

Attach the 3/4" tubing. My tube was naturally bent from being stored on a spool so I oriented that bend to face the direction I wanted the hose to go.

Thread the tubing down to where the bottle will be and mount the filler neck:

Cap on (just a friction fit).

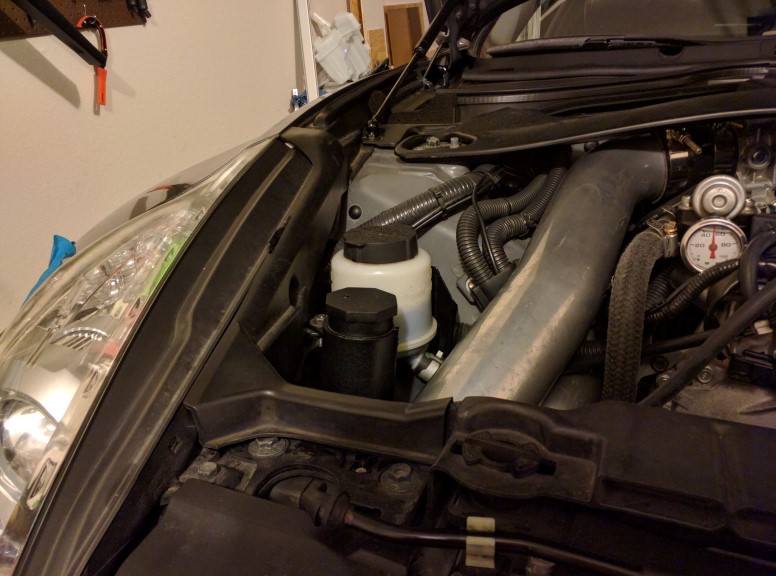

Install the pump into the reservoir and zip tie it onto the bracket. Cut the hose from the filler neck to the appropriate length and clamp it onto the barb at the top of the bottle.

Hook up the harness to the pump and sensor. Connect the washer nozzle hose to the pump.

And filled (you can see the fluid in the hose):

It takes just over a quart if you fill all the way up the hose. You need to fill it slowly to allow air to escape.

Enjoy!!! (Feel free to give me a rep if you use this DIY!)

Tools I used:

Tools I used:

Step bit for drilling holes

crescent wrench for threading in barbs

320 grit sand paper for scuffing PVC and paint prep

Hammer

Clamps

Quick reference hole sizes:

Barbs: 1"

Pump 13/16"

Level Sensor: 1 1/4"