DRIVELINEMOTORING

PRE-ORDER SPECIAL - SSR WHEELS PROFESSOR SP3 l SUPER LOW PRICING FROM DRIVELINE!!

SSR Wheels has added their newest release to the 2010 wheel line up...

SSR Wheels has added their newest release to the 2010 wheel line up...

SSR Professor SP3, 3-piece wheel!! With Tokyo Auto Salon right around the corner, there will be plenty of new demonstrations of this beautiful wheel to come.

SSR Wheels USA has informed us that the first batch will be stateside by Mid-February.

SALE PRICING:

ALL STANDARD FINISHES: PLEASE PM FOR PRICING

ALL SBC/SPECIAL COLORS: AN ADDITIONAL $90.00 PER WHEEL

CENTER CAPS: $150.00 SHIPPED (SOLD SEPERATELY)

A FREE SET OF MUTEKI LUGS WILL BE INCLUDED WITH EVERY ORDER.

CLOSED END:

**Colors Available: Polished, Red, Blue, Black

OPEN END:

**Colors Available: Polished, Red, Blue, Black

OPEN END:

**Colors Available: Polished, Red, Blue, Black

**Colors Available: Polished, Red, Blue, Black

CONSTRUCTION PROCESS AND DETAILS:

SSF Technology

CONSTRUCTION PROCESS AND DETAILS:

SSF Technology

In 1991, SSR learned of the advanced technology known as Semi-Solid Forging (SSF). This technology was being used by the aircraft industry to manufacture parts that required low weight and reliability. SSR then acquired a license to use SSF technology from Alumax Laboratories. They conducted research and development for one year and created their patented wheel manufacturing plant in Nara, Japan. By combining the best features of casting and forging, SSR implemented them in the manufacturing process of SSF. Further research led scientists to develop a process whereby mixing alloys during the solidification process changed the original microstructure of the alloy from a branch-like structure to a globule granular structure. Alumax then perfected the aluminum stirring process, Magneto-Hydro Dynamics (MHD), and created the basis of SSF technology which results in a pure cylindrical alloy billet free of non-metals, gasses, oxides and other impurities. This MHD billet, when heated to a specific temperature, holds a semi-solid form. The billet is then pressed into a mold at a high rate keeping the preferred globule granular microstructure as the new shape is formed. The end product is very dense and strong. SSR is the only wheel manufacturer in the world to produce SSF aluminum wheels. SSR continues to research ways to further develop SSF, creating reliable, durable, and lightweight wheels.

HTM (Heat Treatment Manufacture)

After the wheels go through a spinning process during manufacturing they are heat treated for a second time. This application of heat increases the strength of the wheel. As a result the wheels are lighter and stronger making them ideal for hard tuned race cars and heavier vehicles.

3 Piece

SSR incorporates the latest technologies in the design and manufacturing of its lightweight 3 piece wheels. The three piece wheel is made up of an outer rim, inner rim, and center disc which allows SSR to offer wide range of offsets and ensures proper fitment specific to your vehicle. The inner rim of the wheel is heat treated for strength, using the HTM (Heat Treatment Manufacture) process which allows for the use of a thinner material to save weight. With weight and high strength in mind, each section of the wheel is engineered using separate grades and thickness of aluminum according to its purpose. SSR's racing heritage and manufacturing innovations have allowed the creation of a 3 piece wheel that is both super lightweight and high in strength.

COLORS AVAILABLE:

- SILVER

- FLAT BLACK

- SUPER BLACK COAT

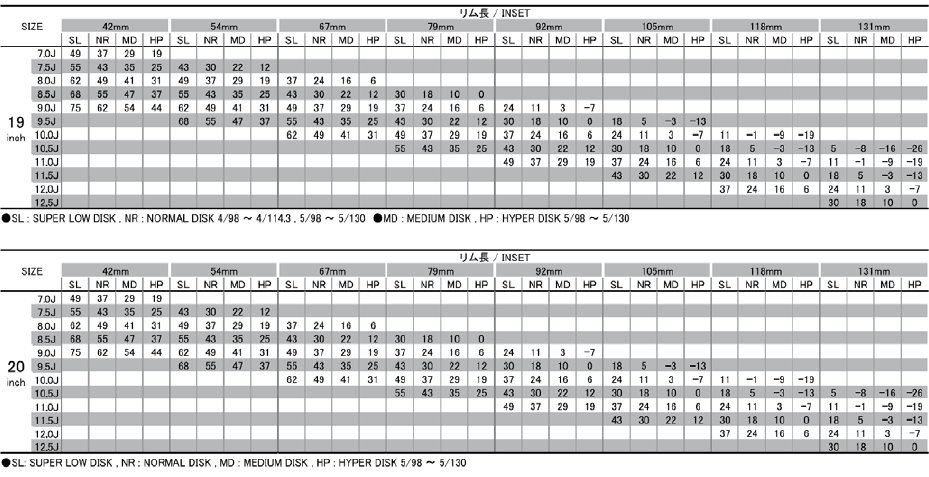

SIZING: