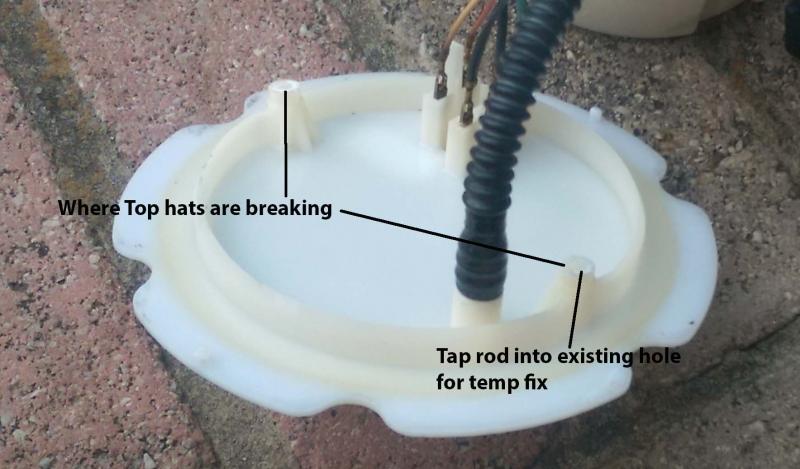

Now for how I fixed mine. (Images below) I am a bit ashamed, but hey it got my baby on the road and it may last a while.

1. Remove piece of broken stand off from rod.

2. With a dryer warm up top hat standoff.

3. With something backing and protecting top of top hat, tap rod into standoff of top hat. There should be a hole there that extends to flange of top hat.

I had to tap pretty hard. Allow to cool. I left it for a few hours. At 1st the rod was being pushed out by the plastic because it was so tight, but then it seamed to stop moving. There is a pretty sharp little barb on end of the rod that snaps into a groove into original hole and I think that barb sank into the plastic pretty well. I tried, using pretty strong force, to remove the rod and I was unable. (Disclaimer-I am not Hercules)

4. Reassemble and place back in tank. This is by no means a recommended fix, but if it brakes and you really need it, it should take about 2-3 hours. If you don't want to wait for cooling and just want to get it back in tank then maybe 1.5 hours. Cost here is only time. When I placed it in the tank, it still had about 3/8" of compression on spring so I know it is on bottom of tank. If you are at the track or somewhere you have no way of getting home, 10 and 8 mm sockets phillips screw drivers and you can be back on the road in no time at zero cost.

Just some advice, tow trucks suck.