After realizing I couldn't borrow my daughter’s car any longer I decided to try and put the pump assembly back together. What I did may not be a permanent fix, but it will hold for a while. This fix of mine relegated me of my only option later(if it does fail) would be to purchase Phunk’s machined top hat.

After putting it all back together my way, the lights came on and I thought of a cheap alternative to anyone who may not want to buy the top hat or needs their baby right now. I am not trying to steal thunder or hurt Phunk’s profit margins, but I believe the option I describe will be a permanent fix and should only cost about $10 to $15 to fix. All items should hopefully be found at local hardware or auto store.

What you will need.

All materials should be stainless

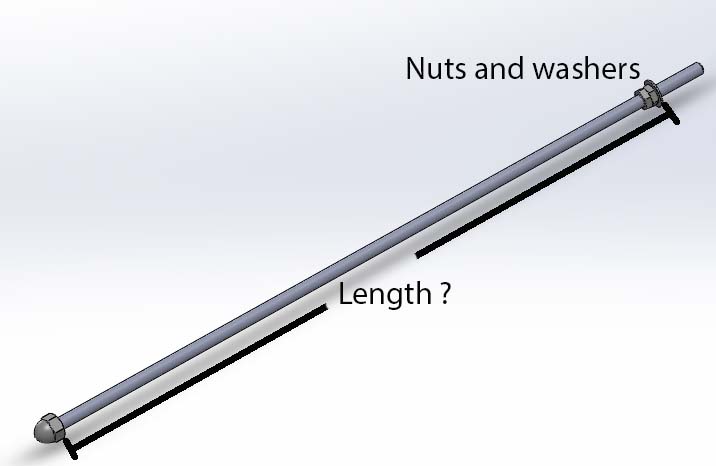

(2) 1ft. pieces of 8-32 all thread

(2) 8-32 cap or acorn nuts.

(6-8) 8-32 thin hex nuts.

(4) thin washers

One tube of fuel safe gasket sealer or JB weld.

1/8" drill

In this description, there are a few unknowns which you guys and gals will be able to be figured out easily.

1. Screw cap nut onto one end. May use a jam nut to lock onto all thread, or just cram the hell out of it. (unkown) Will the cap nut interfere with bottom housing of assembly? If so, may need to grind a bit of nut away for clearance.

2. Slide all thread through lower pump housing with cap nut on bottom. Place two nuts on to other end followed by washer and adjust length to mimic original rod height considering plastic that broke off. Do not forget black spacer and spring on appropriate side prior to placing nuts and washer.

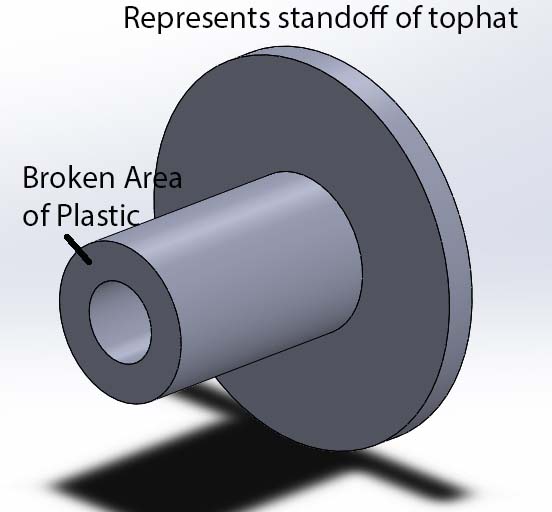

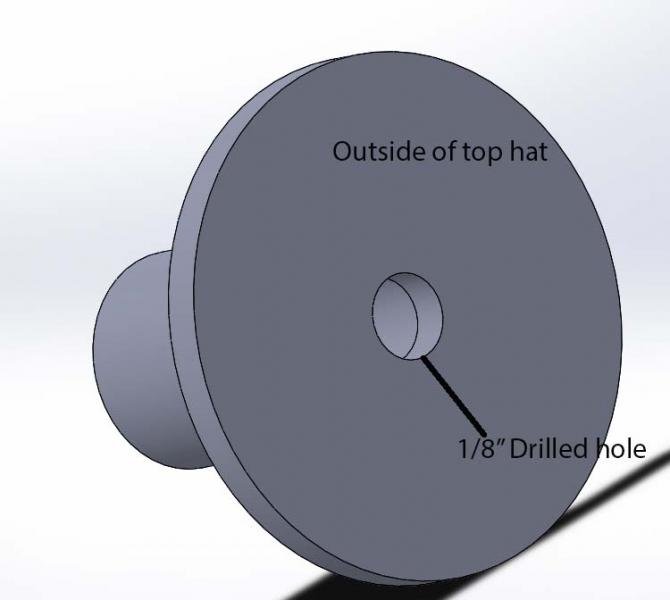

3. Using 1/8” drill, drill the top hat through the stand offs keeping as centered as possible. Using a 1/8” thread will allow the all thread to engage and help seal tank.

4. Using hair dryer, heat up the plastic to soften it. This will prevent cracking while assembling. Just above the nuts or in hole in standoff add sealant or jbweld to help seal tank. Screw the all thread through the hole until the standoff bottoms out on the washer. Adjust to approximate height of original.

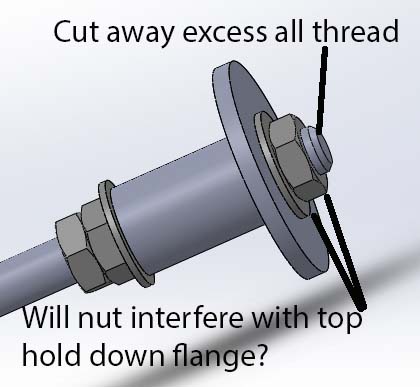

5. Place washer and nut on top and tighten.(may also add a lock washer between washer and nut for peice of mind)

6. Clean all excess sealant from inside and outside of tank area on top hat. Allow to dry and place back in tank.

I don’t know if the top nut and washer will interfere with the flange that holds the pump down. These are things I didn’t measure, because I wasn’t thinking of a better fix when I had it out. Doh!

If someone out there wants to try this fix, I would take those measurements prior to doing all of this.

I do believe this is a permanent fix, because it would take a lot to rip the all thread from the top hat. (it won’t happen) There may be a little trouble trying to compress it in the tank, due to all thread catching the bottom assembly as it slides through the hole. Other than that I don’t know why this would not work.

Let me know what you think and if I missed anything.

If you guys want answer the unknows, I will make a better write up and place it in DIY.

This could also be a quicker kit Phunk could machine for maybe $40-$50. Would be and extremely cheap fix either way.

Pump assembly from Nissan $450

Pump assembly from Ebay $425

Top hat from Phunk $150 - $175

Phunks Justice fix $40-$50 kit.(assumed)

DIY for $10 - $15

Your call!