Quote:

Originally Posted by MadBarber

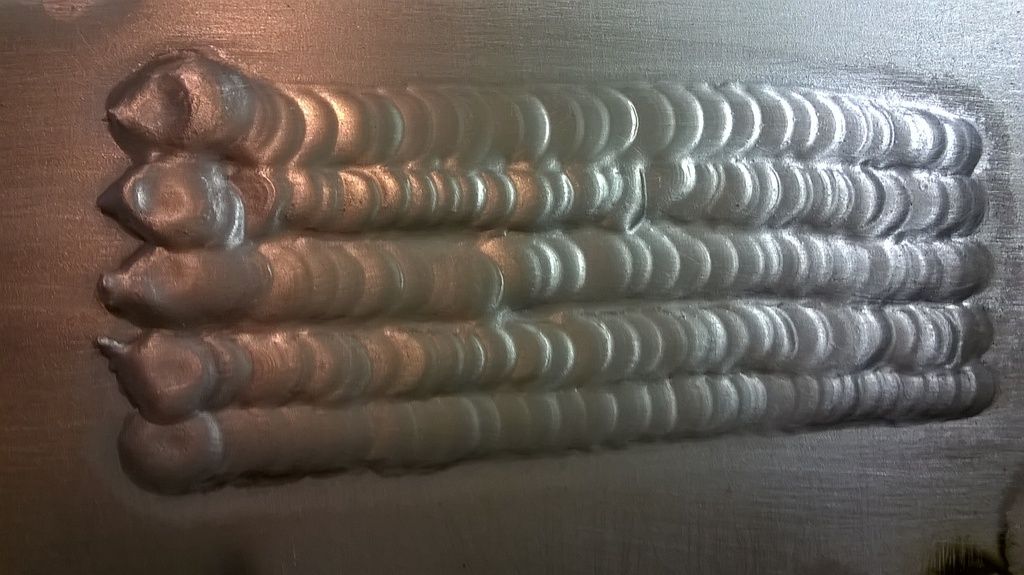

Hey guys, I was getting bored waiting for the turbo installation which hasn't really started yet. So I started practicing aluminum welding. A welder friend of mine told me to practice beat on plate, and I did  . The first 3 days, I was not using the Pedal because it didn't arrive yet. But I was using the Pedal on the 4th day. Here's what I came up with, I understand it's kinda like a mess and it's not going to win any award lol.

The result is a messy plate of 4 days of practicing.

The result is a messy plate of 4 days of practicing.

Here's the 4th day with the Pedal. Just incase you are wondering, I was using 1/16 aluminum plate with 3/32 Red Tungsten, and 1/16 rod on this particular picture. The welding is an inverted Everlast Micro Tig 185 with AC/DC capabilities. What do you guys think, please give me some advice for me to move on. Thanks in advance.

Here's the 4th day with the Pedal. Just incase you are wondering, I was using 1/16 aluminum plate with 3/32 Red Tungsten, and 1/16 rod on this particular picture. The welding is an inverted Everlast Micro Tig 185 with AC/DC capabilities. What do you guys think, please give me some advice for me to move on. Thanks in advance.

I was told by 11Motors that they were busy with a Skyline GT-R, but they'll start the installation on Monday. So I'll get you guys the pics as they go, promise. |

When welding aluminum or any tig welding. Move the tungsten to one side of the weld puddle just before you stop. This way you limit the chance of having a crack in the crater. Also, did you have a round ball on the end of the tungsten, instead of a point? Green band tungsten might be a little better for welding aluminum.