I just thought I would throw this out there to get a reaction from you guys. Been thinking of starting up an offshoot business and run it along side my current tuning business. I will soon become a full Mechanical Engineer and have up until now been engineering struction components on our many drilling rigs. I have extensive time both working with solidworks, including its FEA package.

I am thinking of starting up a service for the backyard mechanics to propose solutions to making their builds a reality. Many of you know the problem and know exactly what is needed to solve the problem, but if your like me its how do you solve that problem. Without accurate 3d models and drawings or a buddy in a machine shop to help you your left scrambling to try and find ways to get what you want made. This usually means calling around and trying to find a fab shop that will build you what your looking for.

I know at least up here there is a market of guys doing engine swaps, putting turbos on cars, and just making crazy awesome builds. These guys usually succeed due to their connections to get random parts made. I know of a local 370Z owner who works in a fab shop, and it shows with the attention to detail on the fabbed up parts he is able to produce. He knows material and knows how to make a random bracket or cover. But not everyone has that connection, but if you had a place to go to make your idea a reality at first in a computer, then physically would you use that service?

A big example that everyone can relate to on this forum is making a manifold adaptor to fit the GTR manifold. There was so much want for this product but it seems to have died off. I have no doubt that I could 3d model a solution and find a way to have it produced.

There are companies doing this inhouse already, Z1 with their clutch relocation product, Fast Intentions with their beautifully made FI kit, just looking at those renders makes me happy, lol. But what about the backyard mechanic?

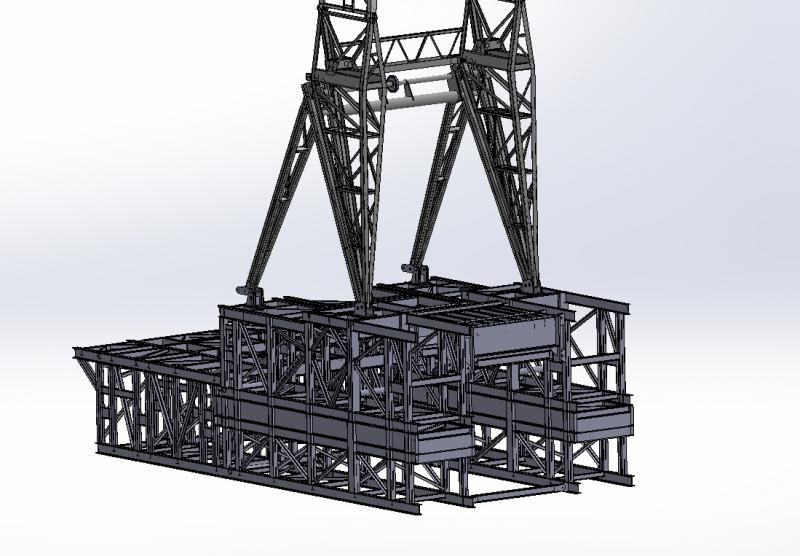

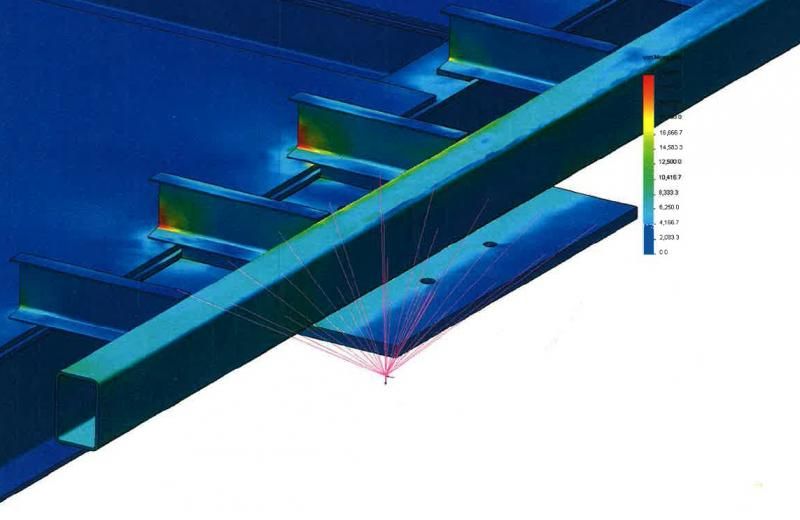

Essentially I am looking to mix my Engineering Degree with my interest in the automotive world and this seems like a good way to do it. Heres a few screens of the sort of stuff I currently use solid modeling for.

Then a bit of FEA analysis on a mounting plate for one of our large winches. I would be able to do flow analysis in much the same way.

Let me know what you guys think! Good or bad I want to hear it. I think there would be a market for it. Even if its a proactive one and jumping on issues I think the automotive community would want fixed or improved.

Mitch