As I am finishing up the next round of kits, I thought I should update this a bit as well. As always, I listen to what my customers provide to me as feedback. There was a couple of minor things that came up during an install. Perhaps others had the same issue, but didn't bother letting me know. Anyway...here are a few small improvements:

The end of the down pipe that mates up to the turbo has been improved to completely eliminate the chance of exhaust leaks, and give the driver a false A/F reading.

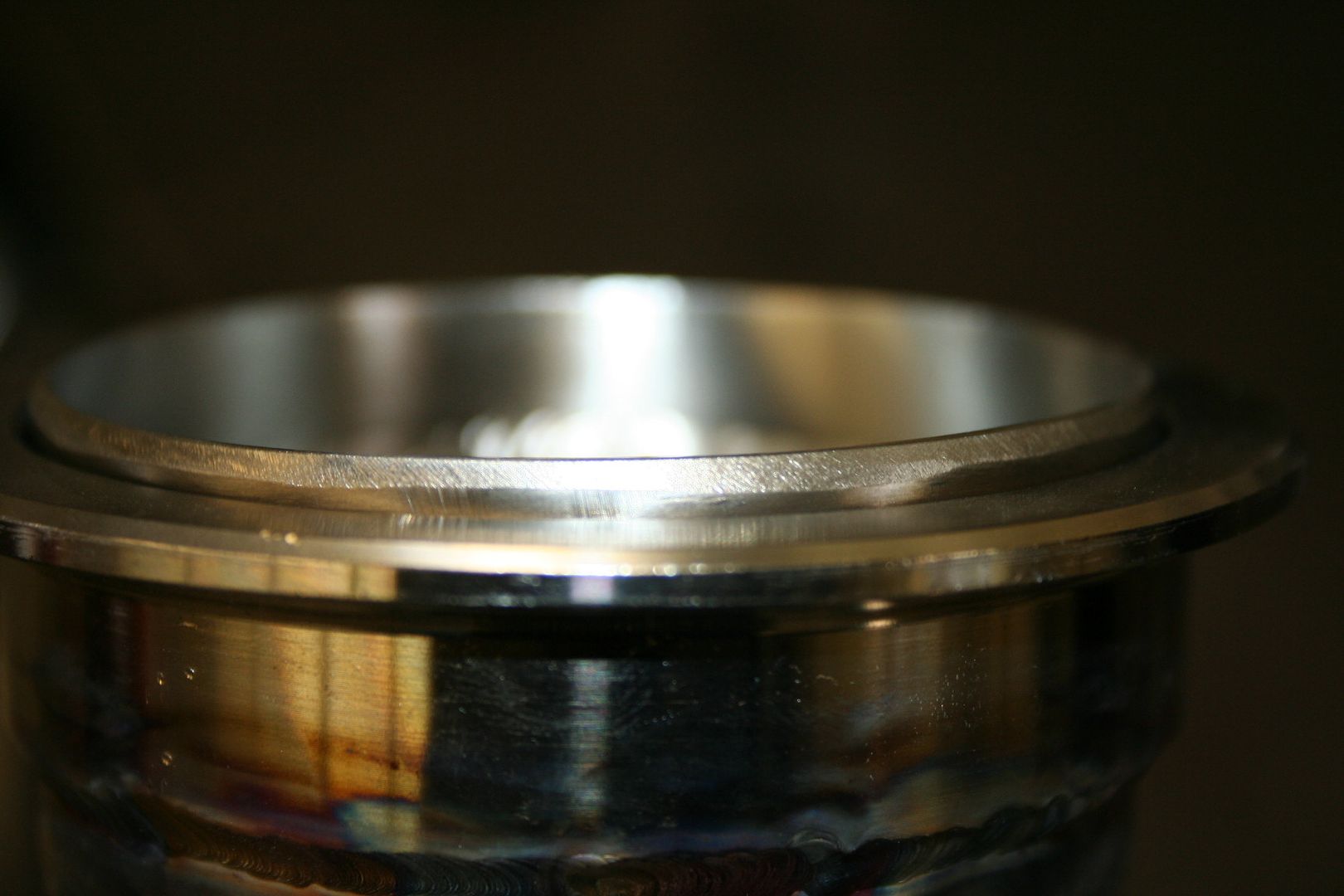

The turbo outlet is bevelled:

and the 3" pipe now sticks out past the V-band flange, and actually slides slightly in to the turbine outlet:

It is much more like a tongue/groove connection.

All the flanges are now welded on the inside vs. outside. This prevents any kind of warping of the flange, so the mating surface is perfectly flat:

(not a great picture):

A few small beads on the outside, and solid weld on the inside. The flanges remain perfectly flat:

3-bolt header flanges are done the same way:

(note how the inside of the tubing looks welded as well, this is due to purging each manifold with argon during the welding process. This is like welding the tubing from both the inside and outside, producing a very strong, durable weld)

Flange stays perfectly flat:

QC is always important, so nothing leaves till it has been assembled, and all the flanges line up perfectly:

The kit now also comes with a 30 row oil cooler.