EDIT (10/25/2013): Finally had a chance to update this post. TL;DR: All is well!

Good news everyone!

As you may know, I had my second clutch master cylinder fail, and I was tired of replacing them with OEM clutch master cylinders. Since I drive my car harder than most people, I was recommended by Joe@ZSpeed to use a Southbend Stage 3+ Drag clutch setup, and it took a heavy toll on the OEM clutch master cylinder. I began my research and development into finding a suitable aftermarket replacement. I searched far and wide and called a few companies, including looking for a direct fit replacement, but it was uncharted waters for the 370Z.

That research was culminated in this thread:

Possible solutions to aftermarket clutch master cylinder

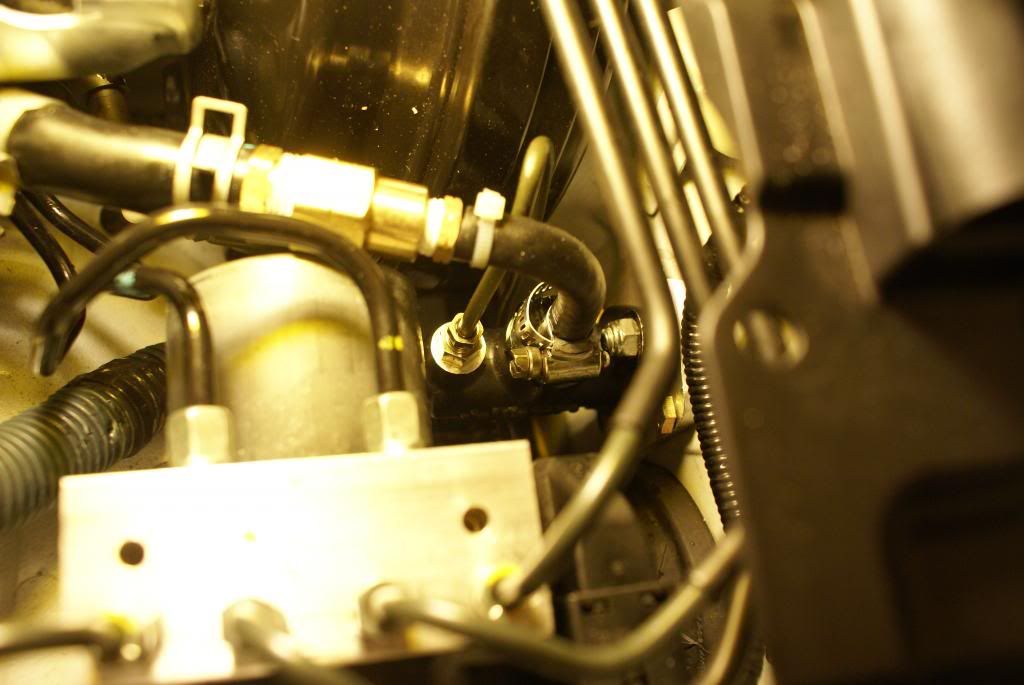

However! I am honestly very proud to announce, barring any race teams or race cars I know of, I am the first person to successfully install an aftermarket clutch master cylinder AND keep the ABS: (thanks Megan370z.)

This is a Tilton Racing 76-Series Racing master cylinder with Grade-8 steel mounting hardware for durability and strength and a custom 6061-Aluminium mounting bracket I machined myself. The brake line is a special alloy brake line that allows high resistance to kinking and vibration and allows hand-bending. All bore sizing and stroke compared to OEM was considered, and this was designed to fit in place exactly like OEM, with grinding of the ABS module bracket as the only modification.

Needless to say, I finished the installation just prior to this post, and barring minor setbacks with parts, fitment, and tools, and bleeding with a friend, it works!

The master cylinder holds perfect line pressure with less dead play than OEM, as well as having no harder rebound or change in engagement point compared to OEM! I just went for a drive, and it feels exactly how it should always feel - strong and firm, but easy to modulate and predictable in its behavior.

I'd also like to note that what you see is what I consider my prototype - if I were to go about it again, I would have parts professionally water-jetted, sourced custom parts to make a cleaner install, and also simple fixes such as found a new clutch fluid reservoir to fit cleanly. Having the OEM reservoir sitting funky is just temporary!

When I started this project, I hoped that it would be simpler to do, that it could become a forum DIY. As I progressed with the install, it became apparent that this was not a simple DIY, but a laborious task. Tracking down fittings, lines, hoses, and nuts and bolts to convert a Japanese master cylinder to an American-made master cylinder was INSANE. I wish I could say that it was simple to do, but that would be somewhat far from the truth. Also, a visit to the dealer might be required, since the ABS module had to be removed from the car.

I'm going to hold my words regarding reliability of this master cylinder until I get lots of more miles and heat cycles through it. I'll be updating every so often to give you guys more news and whatnot!

Also, I appreciate the support in the people pushing me to do this project. I'm glad I was able to successfully develop and install an aftermarket master cylinder into the 370Z. Fingers crossed, but this is hopefully the last time I will EVER deal with the master cylinder!

I'll also be updating the thread with more detail in my part choices, master cylinder places, driving experiences, pictures, etc. when I have more time.

-----------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------

Alright! Finally had a moment to post some pictures!

First off, I'll take some time to eventually post up a step-by-step on how to remove the ABS module, and subsequently, the OEM CMC. This is mainly because if anyone was to do this install, grinding of the ABS module mounting bracket is necessary. But for now, here are some interim pictures so you fellas can get an idea of my thought process.

Here is the main culprit which halts the installation of an aftermarket master cylinder:

As you can see, the OEM CMC is already very close to the ABS module bracket (both illuminated by the camera flash). In this picture, the gap is about a little less than half an inch. To help explain the issue, here is the OEM CMC:

Nissan made a very interesting CMC - where half the body is INSIDE of the interior of the car. Most CMCs, including the Tilton CMC I bought as you can see, has the body of the CMC on the outside, and only the threaded rod to the piston into the car. Naturally, this is quite an issue.

Here is a picture of the ABS mounting bracket, removed from the car:

And here is an isometric view of the bracket (note - this bracket is trimmed already, so it's missing a corner. I wanted to show the other two rubber bushing mounts you couldn't see on the first one.)

In the first picture, you are looking at the corner of the ABS bracket that would be closest to the OEM CMC, and with the rubber bushing removed. Upon inspection after removal, the bracket has 4 rubber bushings that hold the top piece of the bracket to the lower, and the top piece holds the actual ABS module in place. The point of the rubber bushings is to absorb vibrations and to dampen them. Since there were 4 bushings, if I trimmed down one of them and only had 3, the ABS module would still be kinematically stable - i.e., it will still absorb vibrations and not move.

Here is that bracket, trimmed down:

As you can see, I removed quite a bit from the original. I took it to my bench grinder and worked it until I removed what I thought was necessary. I trimmed about a quarter inch past the last remnant of the area for the rubber bushing. It wasn't hard to do, just time consuming because I didn't have gloves and it got REAL HOT.

Even with all this removal, after installing my prototype CMC, I only had about a quarter-inch of clearance! Very tight fit, but I knew it was possible.

There is still room to grind more, but hey, don't fix what ain't broke at this point.

That's the main thing I wanted to share at this point, since it was the crucial step to making an aftermarket CMC work. Like I said, I'll try to get a step-by-step up later to let you guys determine if it's DIY for you guys. ^^ Also! I'll be doing the mileage updates in the second post as well.