I would say I recently installed my NST Pulley kit, but that would be misleading, since I installed them about 3 months ago.

Anyway, I thought I would get around to some quick thoughts on the installation, and my personal review of the kit. Unfortunately this time around, I don't have too many pictures!

Here is a link to the kit if anyone needs it:

NST - The Leader In Nissan 370Z Pulley Development

I purchased a kit from a forum member, that was brand new, never used. I had the underdrive crank pulley, overdrive alternator pulley, and the shorter Gates belt.

Pulley Removal and Installation:

I began my install by jacking the car up on all 4 corners, and removing the the black plastic splash guard. I then promptly began draining the radiator, since I planned on removing the radiator hoses for maximum room to work with. The radiator has a drain plug that allows easy draining.

I then went topside, and removed the radiator overflow bottle, and the two radiator hoses, both top and bottom.

Then for removing the fans, the are only 3 bolts if I recall correctly that hold the top of the fans in place. The bottom has two legs that are seated in holes - just lift the fans and move them away from the holes. There is also a ribbon of connectors on top of the fans that you need to disconnect, or cut away since they have zip ties holding them.

Remove the fan by going UNDER the car - the top has no space.

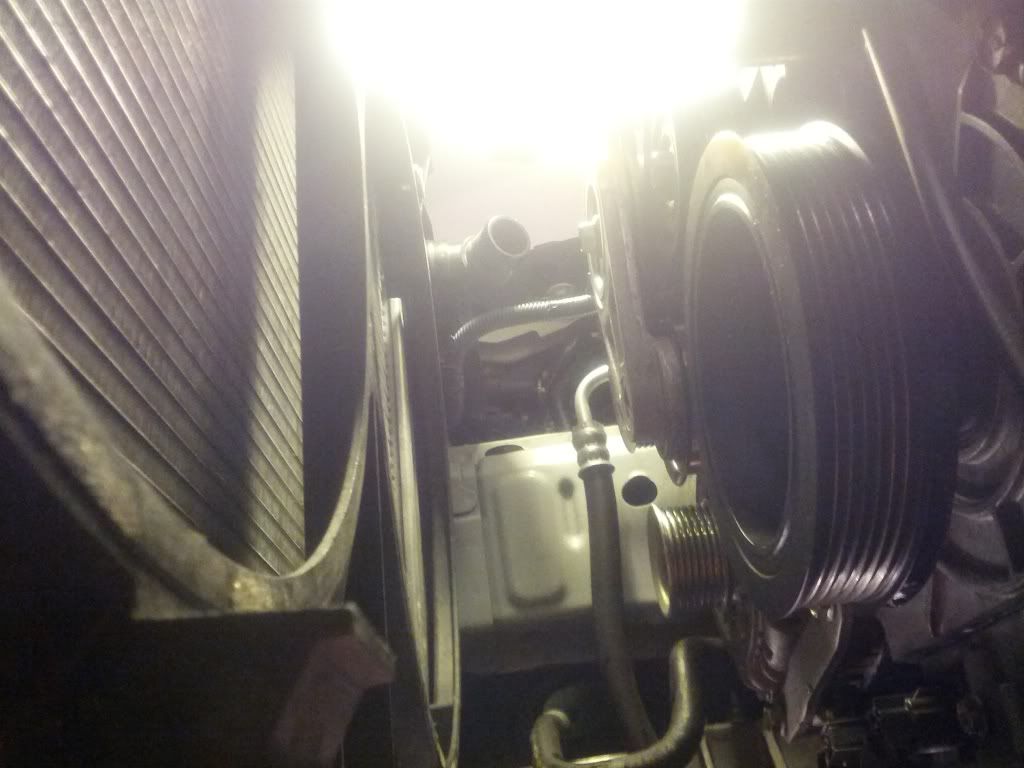

After removing the fans, you have this much space:

Once the fans are out, remove the serpentine belt from the car. The tensioner has a groove that you can place a rod in so you can lock it in place, like so:

Now, for the tricky part...removing the crankshaft bolt.

I'm not gonna lie. The bolt on my car was STUCK. HARD. At one point, I was debating removing my AC condenser and radiator, just to get an impact on the bolt. Luckily, I found a way.

Here's how I removed the crankshaft bolt from our cars.

This looks a little confusing, but it is the spare tire iron, stuck in the U-joint of the driveshaft, closest to the transmission. I put the car in 3rd gear, and wedged the tire iron against the metal frame of the car:

The head of the iron is firmly planted against the frame of the car in this picture. It is not touching anything else but the frame.

With the engine effectively seized, I could now tackle the crankshaft bolt. I took a breaker bar, deep socket, and a 4 foot water pipe I had laying around, and attacked it from the top. Me and a friend pulled so hard, that the rear wheels started to lift due to the slack being lost in the driveline!

But, after much muscle, the bolt went loose, and a satisfying sigh was let out. From there, I proceeded with the rest of the install, using a tiny jaw puller from autozone (someone's journal had this trick in there, forgot who though.), and removed the crank pulley with no hassle. The stock pulley weighs a ton!

The alternator was next. I removed the alternator completely from the car - 3 bolts if I recall held it in place. I disconnected the leads, and as I tried to remove it from the car, I realized I would have to remove the swaybar to get it out from the engine bay. I went the lazy route, and just had the alternator sit on the swaybar:

(Took picture after installing the pulley, haha.)

I took an impact gun to the bolt, and it came off right away. I reversed my removal of the alternator at this point.

For the NST crank pulley, mine was a tight fit. I sanded down the interior edges a bit, and it was a tiny bit smoother. I put the pulley on the crank snout as best I could, then used the crank bolt to seat it the rest of the way. Torqued it back down hard as well.

After this, it was super smoothing sailing. Just reverse everything you did, with the shorter belt, install the fans, hoses, and overflow bottle, and refill the radiator.

Review:

Overall, I felt little to no butt dyno difference. The car does rev faster, however, albeit a small amount. The SRM responds slightly quicker, and just tapping the gas in neutral makes it jump a little higher. It's nothing like a lightweight flywheel, but it's something! Powerwise, I'd say it's had an effect on my car, but that's something for a dyno to prove.

The installation was honestly not difficult, once I figured out the tricks. I'm a self taught shade-tree kinda guy, and it's nothing too crazy if you have the right tools.

I also have driven 4k miles, with not a single mishap or sign of trouble. I checked the bolts after doing my oil recently, and they are tight as a drum. Both pullies are seated nice and firm.