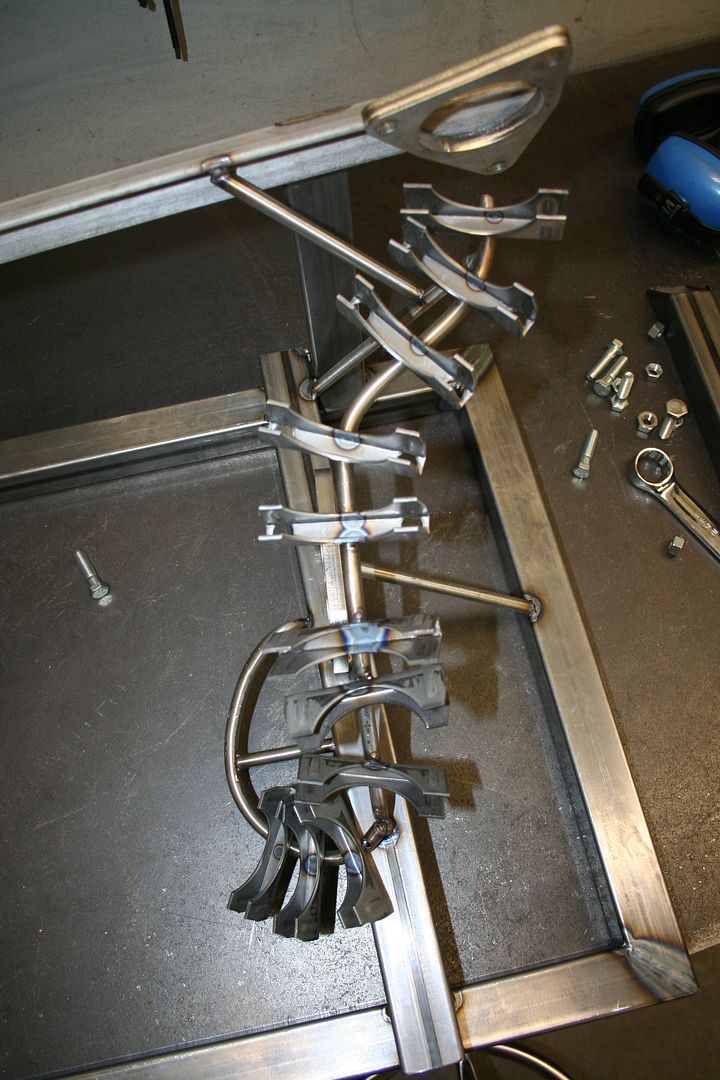

Another few pic of the jig here. As you can see this can be very time consuming, but at the same time must be done right, with high percision.

With the piping out, you can see how it would be very difficult to make a set of pipes that don't fit just right:

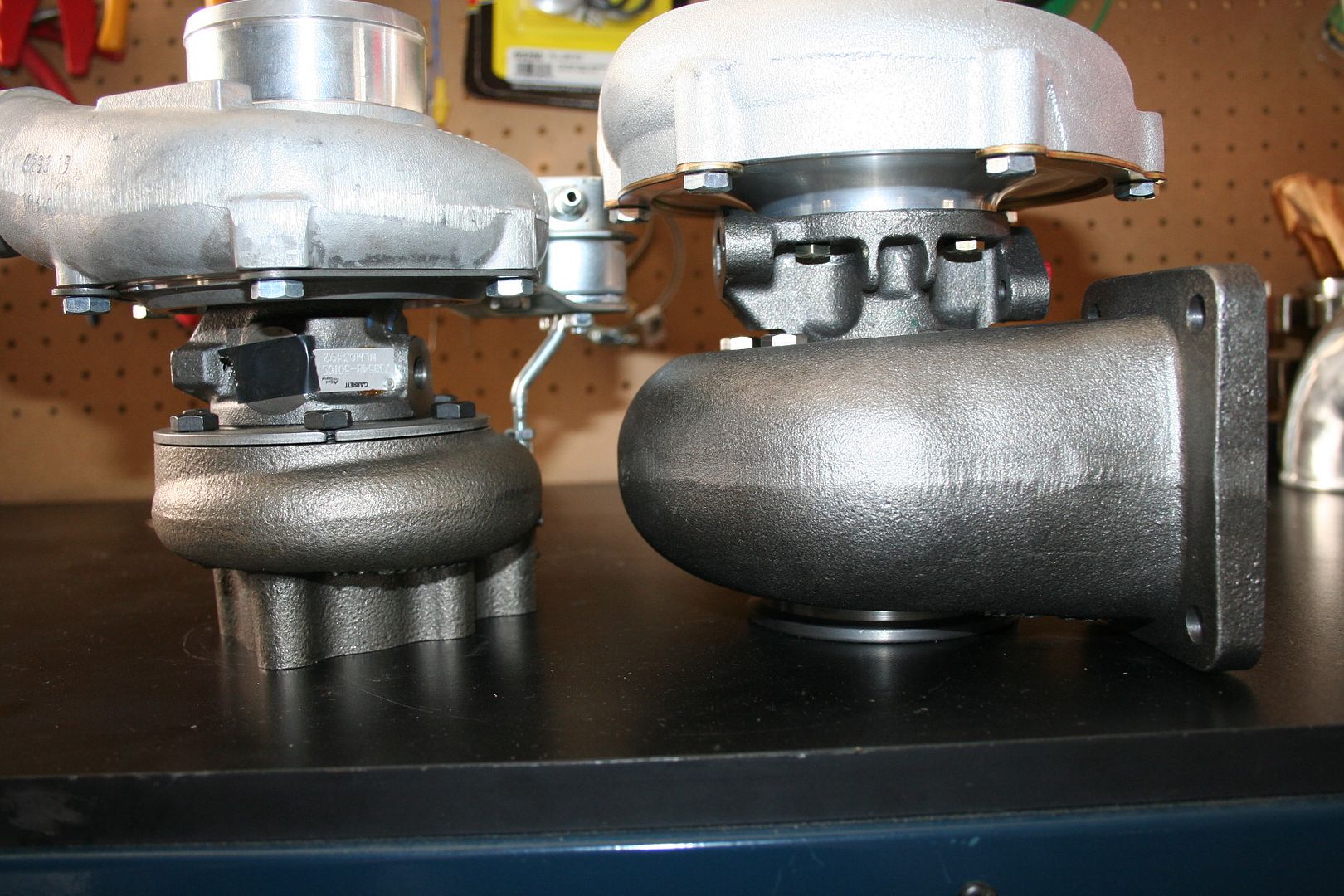

I also got a new 6266 turbo in a couple of day ago for a local build, so I thought I compare it to a turbo that is very common on the VQ twin turbo kits out there.

For starters, have a look at the turbine housing difference in size:

The twin scroll turbine inlets are the same size as the entire inlet of a GT28 (T25) turbo. This is one of the reasons the twin scroll is so efficient. You have both banks (exhaust) powering/moving onc turbine wheel and one compressor wheel vs. two of each.

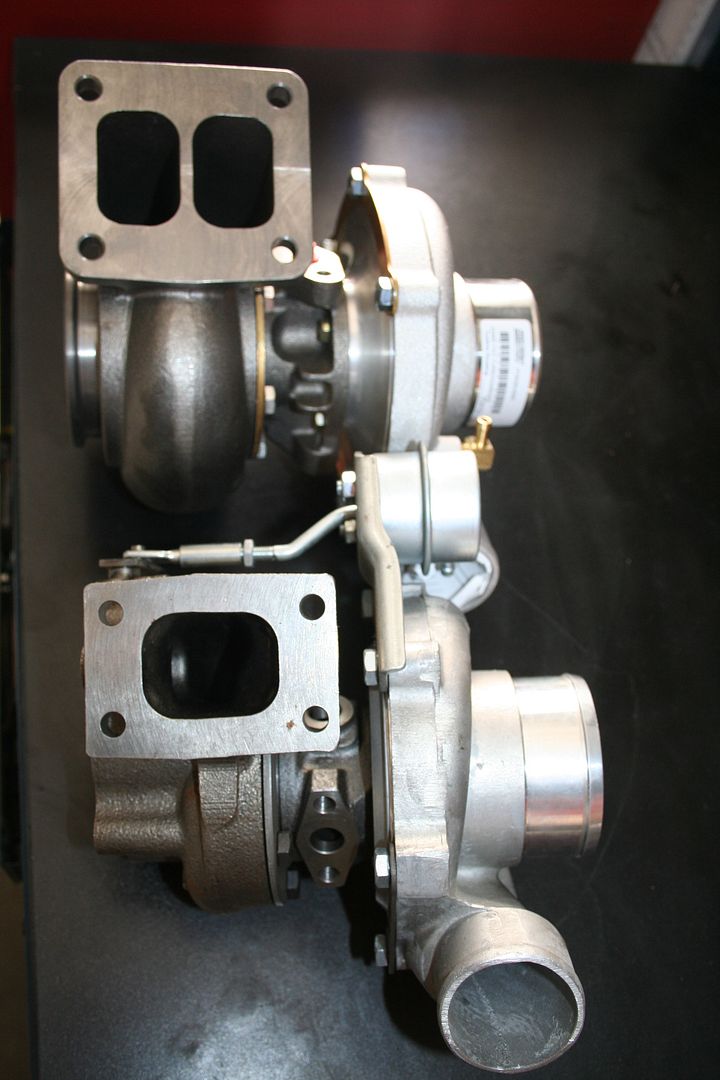

The exhaust side of the turbine housings:

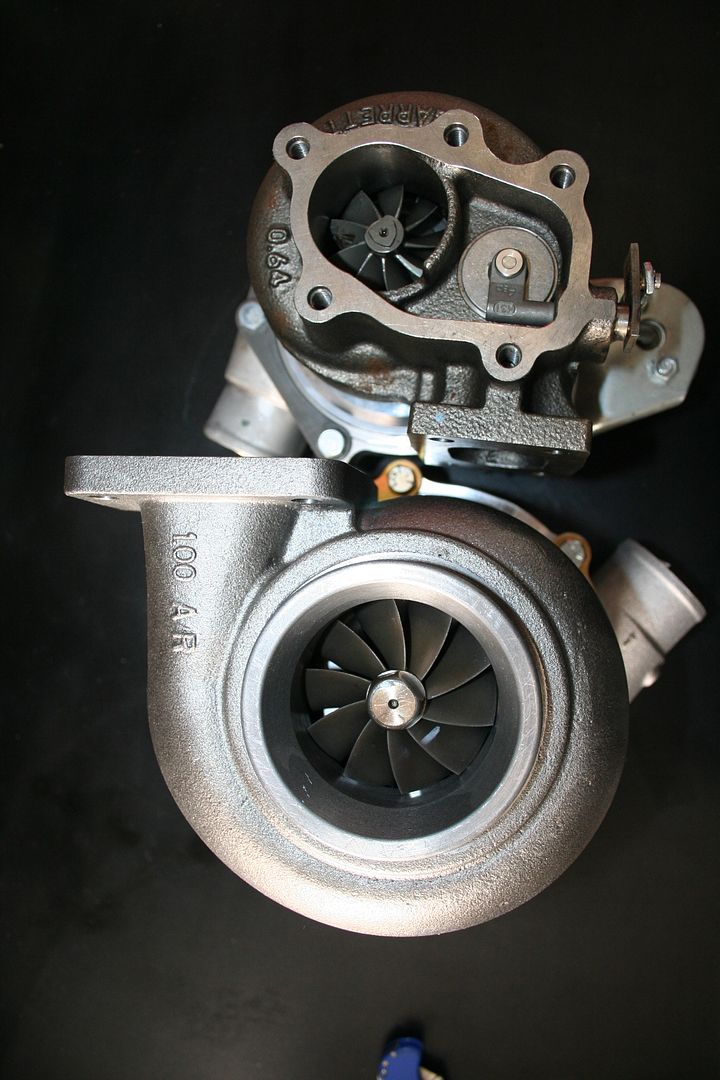

The compressor wheel of course will be much larger as well:

And of course, this is the business end, a 62mm billet compressor wheel: