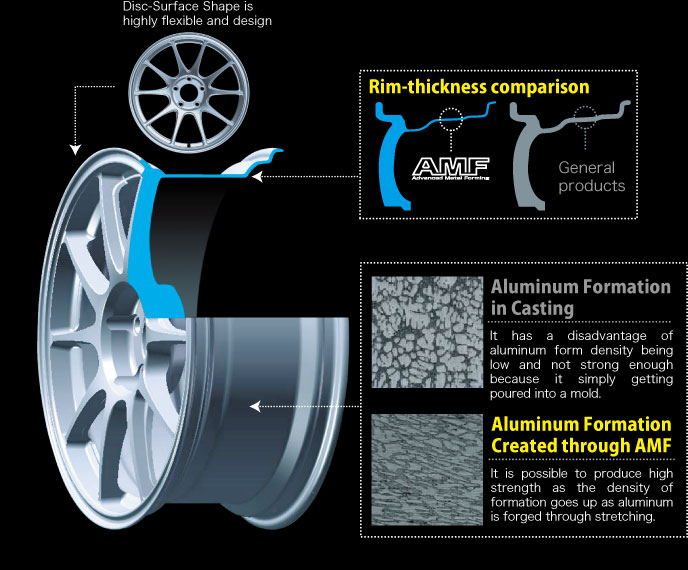

Since this is the tech section, I'm going to give you guys some info on what makes the Weds AMF process better than regular cast wheels. With Weds' Advanced Metal Forming (AMF) techniques, you end up with a stronger wheel compared to traditional casting methods. AMF casting produces a stronger, lighter, wheel. It's a great choice for customers that want the most durable wheel possible but can't spring for the higher end forged wheels.

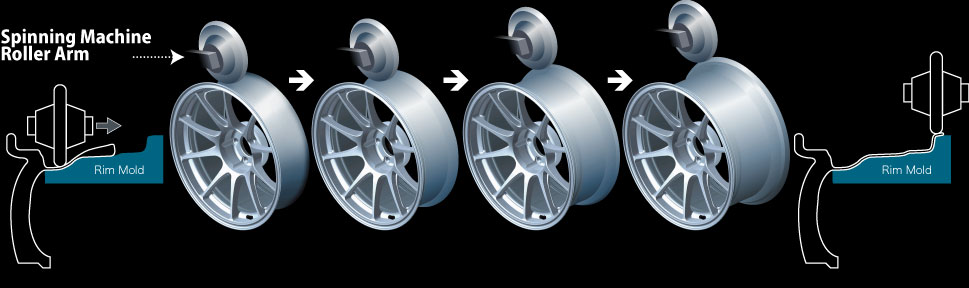

In the AMF process, Weds casts the face of the wheel and the barrel in one piece and uses special forming equipment to mold the metal into the final shape. The 1st stage is casting the wheel, using a flow-form technique. This is the best way to cast a wheel. Once the wheel is cast, it's mounted to exclusive spinning equipment and heated while the rollers rearrange the material according to the rim mold. Once the wheel has been molded, it's handed off to the machining and finishing machines, where the final details are handled.

The AMF process results in a stronger and more flexible wheel because of how the aluminum changes on a macro level. Weds' AMF series wheels have higher stretch strength, durability, and spread than competitors. Take a look at the macro photos of the crystalline structure of the aluminum. Which one looks stronger to you?

In addition to the AMF forming process, Weds also uses N-FRAME technology on the TC105N which provides even more strength by reinforcing the windows between the spokes. This gives the TC105N more strength and a unique look.

Here's the TC105N for those of you that are unfamiliar.

Oh, and just because we're on the subject of strong wheels... Check out this video! This shows why it's important to buy quality wheels.