I was thinking about a cheap solution to this, but I was unsure of the mechanics behind it.

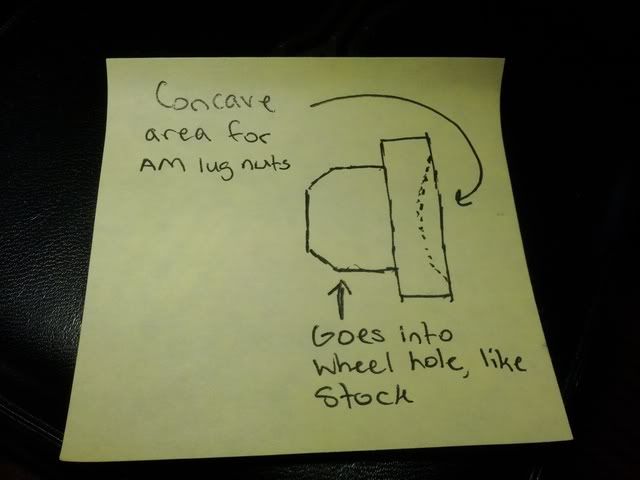

What if someone were to mill on a CNC some "adapters", that had a concave acorn area, and still had a flat part that also went into the wheel hole? So basically, you could use any aftermarket lug nug with this adapter, and the adapter would ensure a snug, tight fit. I couldn't imagine it would be hard to mill at all - if I still had access to a machine shop, I would love to give it a shot. Just use some billets of aluminium or something.

Here is a quick drawing of what I mean:

This would be one solid piece of metal, or it could have another washer so it can freespin like the stock ones.

EDIT: I'm an idiot. I completely forgot about lathes. This would be so easy, it's not even funny.